MRS Logística’s locomotive decarbonisation plans

By José Geraldo Ferreira, Luis Deltregia, Mario Eiras Filho, Milton Brovini

1 November 2022

Shares

MRS Logística is one of the most profitable railways in Brazil. Here, Luis Deltregia, José Geraldo Ferreira, Milton Brovini and Mario Eiras Filho from the rail freight operator explain how their commitment to sustainability is driving future plans to increase service, while lowering emissions.

MRS fuel efficiency programme

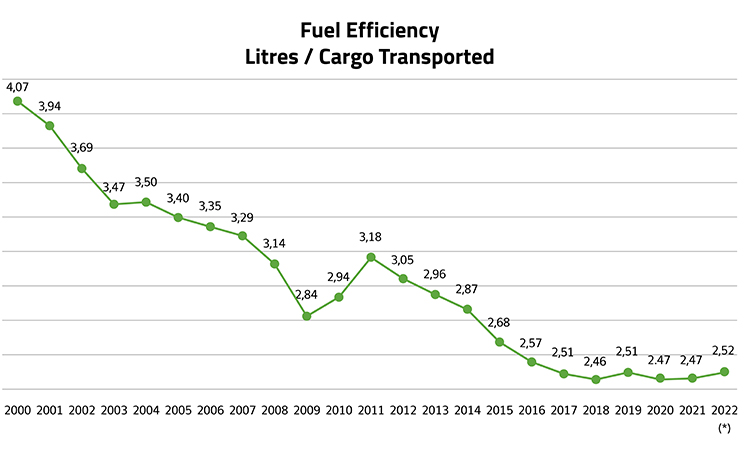

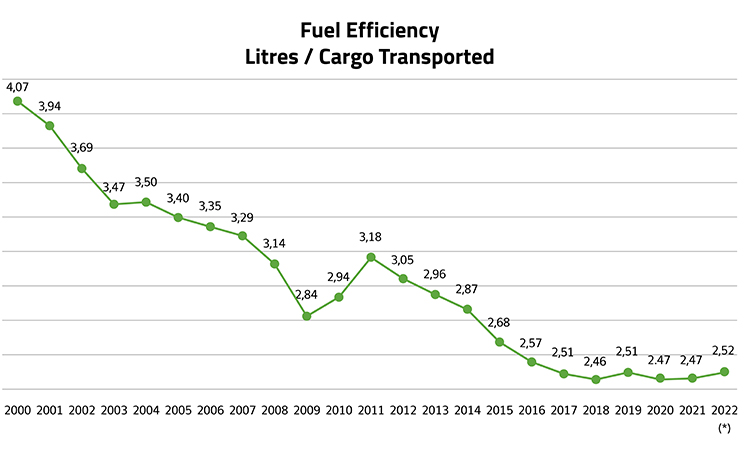

Figure 1: Results of the MRS Logística fuel efficiency programme.

Since 2000, MRS has been operating a fuel efficiency programme which has helped to achieve an impressive 38 per cent reduction in fuel usage per tonne transported.

This programme includes multiple initiatives, including:

- Operator conduction management

- Use of distributed traction on trains

- Track improvement to increase authorised speeds

- AESS (auto engine start and stop) implementation

- New and improved rolling stock.

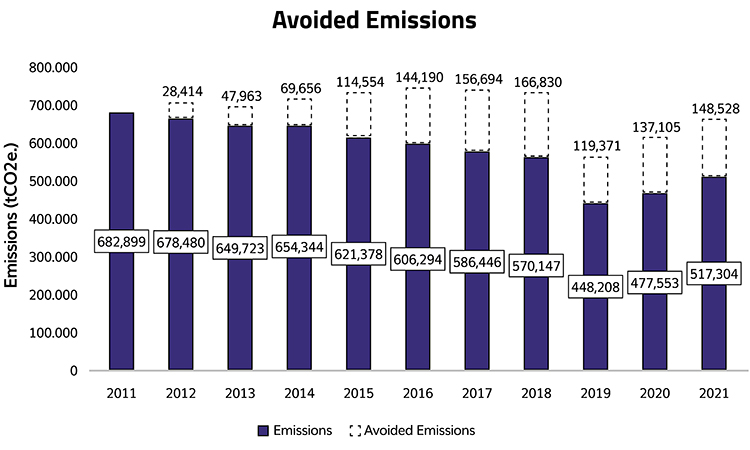

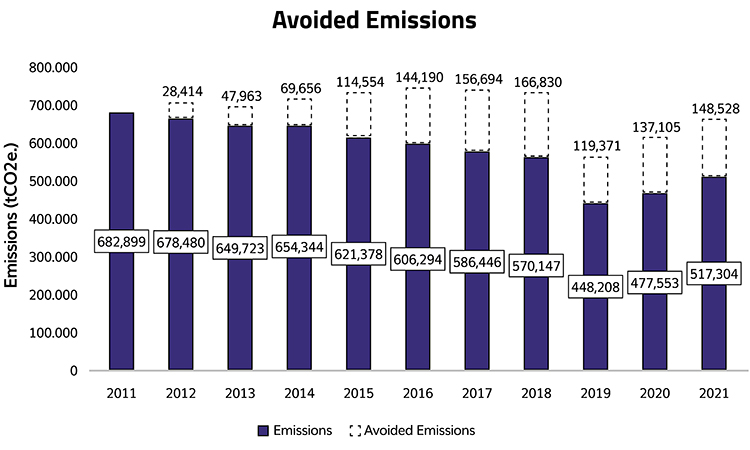

If we examine the last 10 years of this programme, we see that MRS prevented the emission of around 1.1 million tonnes of greenhouse gases (GHG), had 2011 fuel consumption rates continued.

Figure 2: Graph showing the emissions avoided by MRS Logística as a result of the fuel efficiency programme.

The MRS locomotive fleet

As any new company, MRS’s first years of restricted cashflow didn’t allow for the purchase of new locomotives. Instead, we relied on upgrading the existing locomotive fleet with better maintenance practices, microprocessor systems and the acquisition of used locomotives.

Even in this scenario, a consistent fleet upgrade was possible, as low horsepower DC locomotives were gradually upgraded to higher horsepower locomotives, with electronic fuel injection and microprocessor systems.

On a yearly basis, MRS evaluates emissions and publishes an annual sustainability report.

These upgrades came with other technology updates, such as electronic air brake and distributed power. This helped to increase the tonnage hauled per train and train speed, as better control systems increase the locomotive tractive effort and higher horsepower increase train speed – variables directly related to fuel efficiency.

In 2006, a big step was achieved: MRS was able to buy new locomotives. A fleet of 85 GE Dash‑9 locomotives was purchased, bringing an upgrade of 23 per cent in tractive effort and 22 per cent in horsepower over the best existing locomotives (GE C36). A consistent reduction in fuel consumption and emissions was achieved.

In 2007, research into efficiency showed the possibility of success by using AC locomotives. At the time, Brazil had no AC locomotives. MRS was the first railway in Brazil to adopt AC traction as a standard for new locomotives acquisition. GE’s AC44i was the product chosen for this challenge. The supplier was able to create a locomotive that has 75,300 kgf of tractive effort, 4,500 GHP and fitted in the MRS complex tunnel clearance diagram. As the previous Dash-9 locomotives had 52,000 kgf of traction, this 44 per cent gain enabled us to replace four Dash-9 locomotives to three AC44s on the iron ore trains – another step in increasing fuel efficiency.

From 2017 to 2020, cargo constraints and external factors such as the Coronavirus pandemic and a dam collapse on one of the most important iron ore routes, had significant impacts on the volume MRS could transport. This naturally degraded train efficiency and fuel consumption. During this period, engineering efforts were focused on maintenance strategies to keep the company profitable and running on the routes that were impacted by the dam collapse, bringing autonomous train operation up to speed, with unpreceded success on Brazilian railroads.

New locomotive technology programme

MRS Logística has introduced Wabtec’s ES44 locomotives.

In 2020, the proximity of the new concession period and ESG initiatives around the world, including railways and locomotive suppliers (Wabtec and Progress Rail had just unveiled their battery electric locomotives prototypes) shone light on the locomotive fleet renewal. MRS engineering started to track the market for a more aggressive emission reduction plan, focused on the use of new locomotives equipped with batteries for traction.

A locomotive decarbonisation plan was put in place, which included:

- Mapping MRS’s energy regeneration potential for the most representative cargo flows

- Extensive train simulation initiatives

- Roadmap of new locomotive model introduction for the coming years.

The first achievement of this programme was the introduction of Wabtec’s ES44 locomotives. The ES44 locomotive can be considered a prized example of the new generation of Wabtec locomotives for the Brazilian market. These locomotives are equipped with the EVO engine in place of the previous FDL engine, enabling MRS to start using the engine and control platform that will be on Wabtec’s future hybrid locomotives.

These units emit five per cent less than the AC44. If we compare the specific emissions in terms of tractive effort, this number can be as impressive as 31 per cent in comparison with past generation locomotives (in this example, the GE C36).

The next step is to start the decarbonisation programme with a viable transition project: hybrid locomotives.

While working on the electric locomotive constraints, the next few years will be focused on the hybrid locomotive transition model…

After extensive simulations with MRS network data, we were able to establish a train model saving approximately 10 per cent of fuel by using hybrid locomotives in the range of 1MWh of energy storage. These locomotives do not require any extra infrastructure and can take great advantage of MRS’s track profile, utilising dynamic braking during 24.5 per cent of operation time.

What about fully battery electric locomotives?

Simulations have shown several constraints that should be avoided on an electrification programme, including:

- Positioning the charging points with a minimal impact on the current operational model and operator distribution

- Having extra locomotives distributed on charging points to replace the ones under charge

- Electricity availability

- MRS’s trains require electric locomotives with an energy capacity not available on the market yet.

MRS Logística operates a fleet of 770 locomotives and 19,000 wagons.

While working on the electric locomotive constraints, the next few years will be focused on the hybrid locomotive transition model, with prototype acquisition and extensive testing of the new battery systems, maintenance and operation training and overall product enhancements.

Partnerships with acclaimed universities will help MRS to refine train models so we can reduce energy demand while the locomotive producers increase battery capacity.

More time spent on deeper studies and market maturing will not put MRS in first place in terms of electric battery usage, but will certainly allow MRS to make a smarter change, using more mature technology, without losing sight of the main reason for this: GHG reduction, not only from the equipment, but in the energy source as well.