Additive manufacturing for brake systems and pneumatic controls

Published: 12 April 2023

Share this post

- Like

- Digg

- Del

- Tumblr

- VKontakte

- Buffer

- Love This

- Odnoklassniki

- Meneame

- Blogger

- Amazon

- Yahoo Mail

- Gmail

- AOL

- Newsvine

- HackerNews

- Evernote

- MySpace

- Mail.ru

- Viadeo

- Line

- Comments

- Yummly

- SMS

- Viber

- Telegram

- Subscribe

- Skype

- Facebook Messenger

- Kakao

- LiveJournal

- Yammer

- Edgar

- Fintel

- Mix

- Instapaper

- Copy Link

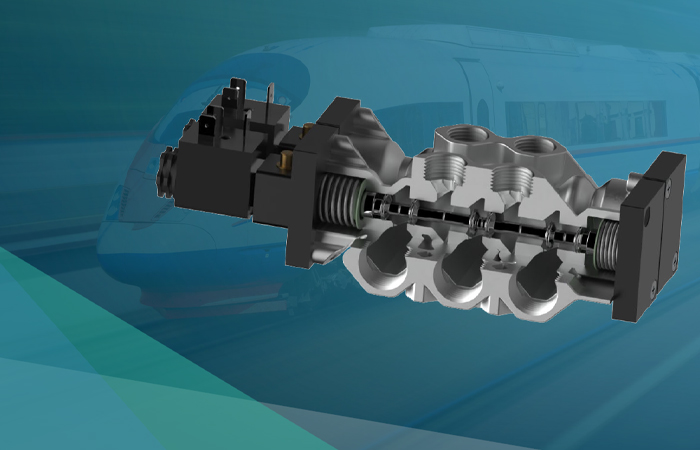

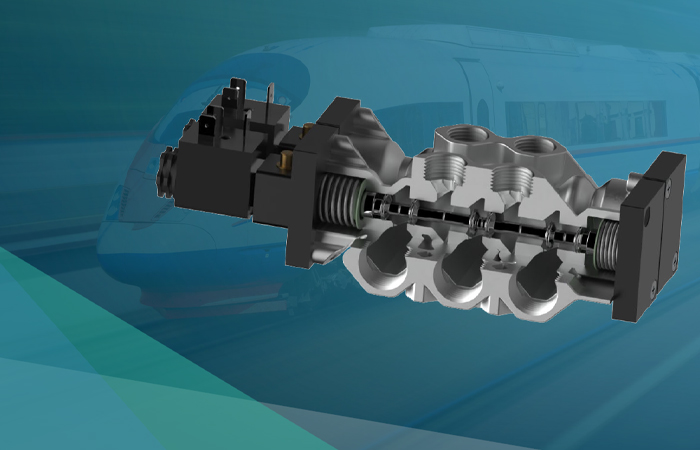

Additive manufacturing can help innovate and optimise pneumatic control applications by enabling customised component consolidation and part count reduction that result in more efficient assembly and maintenance processes.

Design more reliable and more efficient pneumatic manifolds.

Commercial transportation rely on compressed air and pneumatics to efficiently operate and control vital vehicle functions. The ultimate target for design and manufacturing engineers is to minimise points of failure in these systems, in this case, points of leak and reduce part count and dependency on multiple suppliers to reduce service incidents and speed up maintenance.

Additive manufacturing can help innovate and optimise your pneumatic control applications by enabling customised component consolidation and part count reduction that results in more efficient assembly and maintenance processes, reducing inventory costs and supply chain logistics and increasing overall system efficiency at the same time. The resulting component reduces opportunities for leaks, resulting in better product quality, improved reliability and enhanced service with simple and accurate troubleshooting diagnostics.

Download the brake systems and pneumatic controls application brief to learn:

- The benefits of using additive manufacturing for manifolds

- Design for additive tips

- Critical success factors when bringing on additive manufacturing.

Paid promotion supported by 3D Systems.