Track works where design and resilience go hand-in-hand

Posted: 19 April 2018 | RAIL.ONE, RHOMBERG SERSA RAIL GROUP | No comments yet

On 22 April 2017, the Bergen tram line, Bybanen, opened its new airport link, connecting Bergen city centre with Bergen Airport in Flesland. This article1 explores how the new tram stations and the airport terminal platform rely on resilient slab tracks adopting Bybanen’s innovative open city design.

Bybanen’s Open Design uses distinct contrasting colours and materials to enhance predictability and passenger safety. Credit: Bybanen A.S.

Improving connectivity in the Hordaland County, especially in its largest municipality – the City of Bergen, has become the major objective of the tram line expansion project. The project started 15 years ago when the Hordaland County, Bergen City Council and Norwegian Parliament decided to invest in a new transit system for Bergen, known as Bybanen. After the final budget for the project was approved in Parliament, construction formally started in January 2008.

The first stage of the project was built by the municipality, financed by the state and a road toll ring surrounding Bergen. The overall infrastructure project became known as the Bergen programme. The expansion reduced road congestion, improved traffic, created high levels of passenger and resident satisfaction and boosted housing construction around the new stations of the new tram line. Surrounded by mountains, the county and the City of Bergen provide ideal conditions for public transit. The population is naturally concentrated within several nearby valleys, which are up to two kilometres wide and radiate from the valley’s centre. The light-rail tram therefore acts as a multiplier for the community transit, off-loads capacity from the busiest transport corridors in the region and provides an attractive alternative to car-driven traffic. The ticketing system allows passengers to use all means of transport (tram/bus/boat) for the same price, further enhancing its popularity within the region.

The tram line was built from 2008 to 2015. The first Bybanen line opened in the summer of 2010 with a total distance of 20.4km with roughly 40 per cent of the line consisting of tunnels. The maximum speed is 70km/h and the highest inclination is six per cent. With small curve radii occurring frequently in the city, the smallest curve radius on the line is 25m. These characteristics, coupled with high precipitation volume and frequency, provide challenging construction conditions and material requirements that must be carefully anticipated in the trackwork design.

Bybanen Utbygging is the planning authority that drives the expansion of Bybanen and is responsible for all design aspects and coordination with other authorities. It carries out the detailed track system design and the detailed design for the construction, involving civil works and track works.

Rastoelen is one of the new stations along the airport link. This image shows a concrete cover layer along the station platform. One the right-hand side, typical housing construction can be seen. Credit: RAIL.ONE

The Bergen-Programme: Driving local infrastructure

Today, the expansion project is mostly financed through the Bergen-Programme. A key positive side-effect of the new tram lines, alike to the new airport link, is the improvement in housing construction along the new tram lines. Thousands of new apartments are being built near to the new stations and it has been estimated that the value of new housing construction corresponds to 20 times Bybanen’s initial infrastructure investment.

An award-winning light-rail network

In 2011, Bybanen won the international ‘2011 Worldwide Project of the Year’ against other nominated light-rail projects such as the tram network of Dallas, USA, the Angers tram in France and the Gold Coast tram in Australia. In the award declaration, the jury announced: “This fantastic system is a role model for tram projects worldwide” and further emphasised how the efficient design and planning enabled the first line to be realised within only two years, and within budget. All previous estimations of passenger volumes have been surpassed.

This was the first major prize and one of the largest and most prestigious awards for the Bergen tram project. Within a few years, the Bergen tram project had evolved from a merely regional landmark. In 2012, Bybanen won the ‘Collective Traffic Award’ for appealing to new passenger customer groups and providing attractive public transport and the ‘BOBY-award’ by the Norwegian Housing and City Planning Association, for excellent cooperation between authorities, resulting in a high-quality community project. In 2013, the City of Bergen won the ‘City Environment Prize’, a combined architecture and environmental award for cities that sustainably improve the city environment. The jury stated in its declaration that the City of Bergen had a clear vision for infrastructure and public transport, development of housing and a sustainable tram line expansion programme. Two years ago, Bybanen won the ‘Innovation Award for Uniform Design’ in the transport and furniture/interior design categories. The jury explained: “Bybanen was the first railway project with a uniform design in Norway”, calling the project “courageous and innovative”. The jury further explained that the tram line had become the most preferred means of transport in Bergen and recorded positive effects for the whole community. Acknowledged through all the mentioned awards, Bybanen is today an international light-rail reference.

Steady passenger growth beyond expectations

Gunnar Levring is Rail Engineer Design Manager at Bybanen Utbygging, a county agency reporting to the Hordaland County. Bybanen Utbygging is responsible for design aspects and coordination with other authorities. Credit: Bybanen A.S.

Gunnar Levring, Rail Engineer Design Manager at Bybanen Utbygging, said: “From 2010 to 2014, 50 per cent more passengers were recorded in just four years and in 2015, 10 million passengers were reached2. The average daily passenger volume is estimated to be between 40,000 and 50,000, which is double the volume compared to an early estimation seven years ago. Skyss, the organisation responsible for the ticketing system and timetables, expects an annual passenger growth of four per cent. This is one reason behind the further expansion of the Bergen tram line. Another approach has been to use new extended 42m-long trams (compared to previous lengths of 32m). It is expected that the 42m-long trams will accommodate an increased number of passengers, up to a total theoretical capacity of 277 passengers per tram.

Design and resilience go hand-in-hand

Bybanen’s overall objectives are the safety of its tram network, long-term stability, reliability and positive passenger experience. According to Gunnar, one of the most characteristic visual design elements of Bybanen is its ‘Open City-approach’: The open structures without fences and lack of obstructing elements close to the tram line. Other important elements are the white boarder lines of the platform edges, acting as dividing lines between roads and rail tracks.

Gunnar pointed out: “Design provides high predictability and safety for passengers and is strongly related to customer perception. We have had many positive comments from people with impaired vision that confirm this. The contrasting colours of the materials, the white marking lines and the track top cover enhance the passenger-felt predictability and the overall safety.”

Bergen is known for its high precipitation volume, corresponding to approximately two metres of rain annually, 80 per cent humidity and rapidly shifting freeze/thaw cycles. Gunnar said: “Due to the local weather conditions, the tracks have to be well protected from water ingress. In the city’s shared traffic areas where trams and buses pass over the track, de-icing salt is spread during the winter months to facilitate the transit of public buses. The combination of rain, humidity and de-icing salt can create long-term damages on the rail track. From an engineering design perspective, the interface between the rail and cover layer is therefore crucial.

In the winter months, there is often ice on catenary overhead lines and our service car will have to remove the ice and new snow lying on the tracks during maintenance shifts. In all new station tracks along the airport link, including the new airport terminal, maintenance consists mainly of high pressure water cleaning. In the Kokstad Depot, resilient track solutions provide a solid protection for the rail from the negative influence of chemicals used in the tram cleaning operations.”

The Bybanen Expansion project

The most recent line extension, the Phase 3 seven kilometre-long project, starts at the Lagunen station and ends at the airport in Flesland. The tram line construction started in 2013. Only after the Flesland Terminal station had been constructed and finalised was the line finally inaugurated on 22 April 2017. Close to the airport in Kokstad, the extension line connects to a Tram Repair and Maintenance Centre, one of the most modern tram depots in Northern Europe. The 70-acre property has a capacity to maintain 80 vehicles and provide parking for up to 45 trams. The depot was constructed in close cooperation with the company Stadler, which supplies tram vehicles and maintenance services to Bybanen AS, the owner of the Bergen tram network.

RHEDA CITY was designed with a full rail encapsulation profile, a sealed rail providing protection against water ingress and possible effects of electrical stray currents. Credit: RAIL.ONE

Selecting the track work suppliers for the airport link

At the beginning of the project a consulting company was entrusted with the task of suggesting various slab track systems that could provide the resilient, well-proven slab tracks on the station platforms of Rastoelen, Sandslivegen, Sandslimarka, Kokstad, Birkelandsskiftet, Kokstadflaten, Kokstad Depot (repair and maintenance depot) and the Bergen Airport at Flesland. Gunnar recalled: “The main concern was the interface between rail and track, making sure the track system was resilient enough against any influence of water, humidity or de-icing salts, that it allowed for a precise and robust geometric position of rails during installation, providing aligned tracks throughout its lifetime and that the slab track could be adapted to various cover layers like asphalt, concrete and grass.”

Gunnar continued: “We wanted to make sure that the system had been used extensively in city and peripheral traffic over many years and that it was well-proven with many solid project references under comparable traffic and weather conditions. The ideal slab track should have a long life-cycle and allow for future maintenance operations, like the exchange of rail approximately every 40 years. After careful comparisons between the different systems, we selected the RHEDA CITY system. The construction company Rhomberg Sersa Rail installed the slab track solution and concrete sleepers by the supplier RAIL.ONE3. During the track works, the concrete sleepers for the ballasted tracks sections and RHEDA slab track for the station platforms were installed within the targeted time schedule. Apart from the station platform tracks, the RHEDA CITY slab track was also installed in the cleaning tracks of the Kokstad Tram Depot.

“I would like to mention that the flexibility and experience of the track work contractor is essential. Civic works often get delayed and then the track works may have to be implemented at short notice with a narrow time window. After the track works were completed, signalling work and the overhead lines were installed in the final stage of the project.”

RHEDA CITY at Bergen Airport terminal platform in Flesland. Photo Source: RAIL.ONE

Continuously supported track with encapsulated rail

Based on Bybanen’s project specific requirements, the RHEDA CITY slab track system was modified in close cooperation with the involved consultant. This resulted in a tailored solution, meeting the typical weather conditions in Bergen. The core design concept from the RHEDA LRT project in Dublin was used as design benchmark model. In the Dublin project, resilience against high precipitation was one of the key features. This required an optimised encapsulation of the rail-slab-interface. In the Bergen airport link station platforms, RHEDA CITY was designed as a continuously supported track. This track type uses RHEDA bi-block sleepers combined with a full rail encapsulation profile; a sealed rail providing protection against water ingress and possible effects of electrical stray currents. The continuously supported track further enables an easy and high-performance track installation process and provides optimum track elasticity. The track elasticity achieved in the project ensures a long life-cycle of rail, slab and tram wheels.

System flexibility and solid track geometry

In order to reduce long-term maintenance works, such as the correction and repair of gauge widening effects in narrowed track alignment curves, as well as a means to provide long-term solid track structure, the RHEDA CITY system was designed as an embedded track in the station platforms of the new airport link, using a concrete supporting layer. This resulted in an accurately aligned and highly resilient track structure, able to withstand high precipitation volumes and frequent recurring frost cycles.

In the washing section of the Tram Depot, the RHEDA slab track was modified into an open formation track to ensure water, oil and detergent-resistant properties. The RHEDA CITY design concept implemented in the depot washing station included coated fastening system components, providing corrosion protection to further provide additional stability against de-icing salts and higher chemical resistance for a long-lifespan of the track.

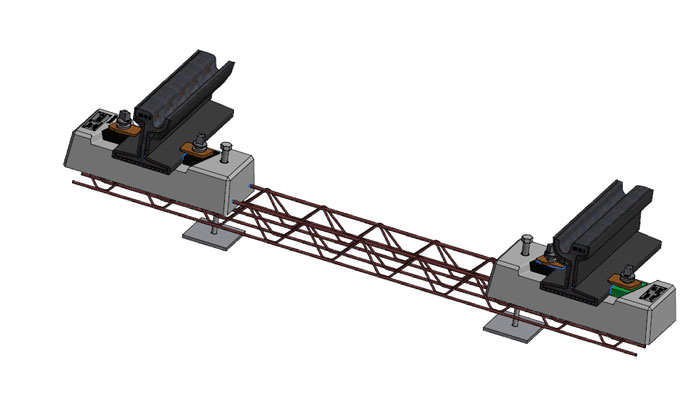

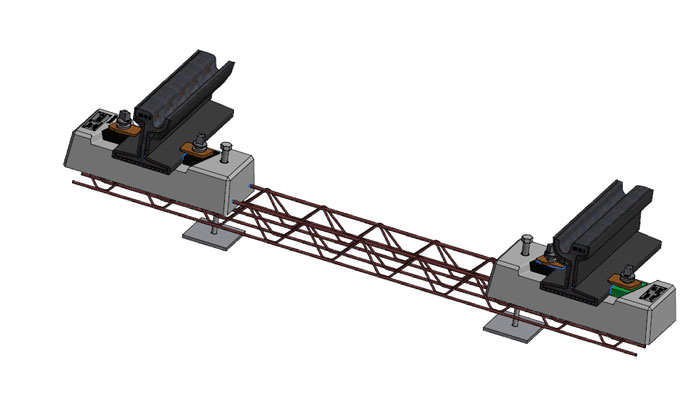

To ensure a solid construction of the slab track, designed for the loading conditions and stresses caused by tram and mixed traffic operations, RHEDA CITY bi-block sleepers consist of steel lattice girders, connecting two concrete blocks with one another. This solution provides a solid foundation for the encapsulated rails, supported on the bi-block sleepers, fixed into the in-situ concrete layer. An additional feature is the optimised adjustability of the fastening system, pre-assembled on the RHEDA bi-block sleeper, which enables an ideal track alignment.

RHEDA CITY bi-block sleepers are available for all types of rails, both vignole and grooved rails and are easily adaptable for all gauges. The RHEDA CITY slab track system can easily be modified for any track cover concept design, such as concrete, paving stone or asphalt top cover layer, open formation tracks with exposed rails and grass layers. Solutions are also available for RHEDA CITY bi-block sleepers in case of planned supports for guard rails, guide rails and derailment devices as well as concept designs with three or four running rails, as in the case of tracks with various tram lanes.

Construction phase

During the construction phase, Bybanen monitored all works through its construction manager, checking on the work status, conducting weekly meetings, safety walks and material concrete tests – all to make sure that the material used, staff procedures and track work quality were in line with construction regulations and predefined requirements. Bybanen’s construction manager was assisted by a contract manager who reviewed and followed-up on contractual issues during the construction phase.

The construction works stood under high time pressure, due to delays. These were primarily caused by civil works, such as tunnel construction. The lost time needed to be caught up during the track works. As an example, the track works in the vicinity of the Flesland airport were shifted to night to ensure the completion of parallel works on the tunnel lining and that the deadline set by Bybanen could still be met.

Other interesting work entailed the installation of unique black-coloured concrete at the Rastoelen and Birkeland stations. The black-coloured surface concrete had to match the general safety system of Bybanen and the accompanying colour-effects scheme. These colour specifications were carefully selected by Bybanen after considering multiple colour samples. Furthermore, the design of the complete tracks on the main line and in the depot responded to the different requirements in those areas. Thereof, various systems were used for different functionalities.

A further challenge was encountered at Rastoelen station, where ‘damper mats’ had to be placed under the RHEDA CITY track system to decouple it from the sub structure. This influenced the achievement of exact track geometry. Fortunately, a successful solution was found thanks to the experience of the on-site team.

Construction phase of RHEDA CITY at Bergen Airport terminal in Flesland. Credit: Rhomberg Sersa Rail Group

Due to the coordination and close cooperation between the supplier RAIL.ONE and the Rhomberg Sersa Rail Group, various technical and scheduling challenges could be overcome. Project Leader of Rhomberg Sersa Rail, Lukas Mair, said: “We are proud that once again a quality product was delivered on-time to a satisfied client.”

After a construction period of 22 months, the main line, as well as the depot, was handed over to Bybanen for the necessary test runs. Gunnar commented: “Overall, we are very satisfied with the track solutions and the performed track works.”

Future outlook

In the future, tram extension Phase 4 and 5, the coordination with the City of Bergen will become very important and will involve land purchase. The Phase 4 extension line, planned to be 10km-long, will start in Bergen city centre, Byparken, move westwards and end in Fyllingsdalen. Alongside this, Phase 5 will start in Byparken and end in the Northern region of Aasane. The preliminary plan is that Phase 4 will open in 2022.

In both extension lines, there will be predominantly shared traffic lines for trams and buses in the city. It is most probable that asphalt will be used in the top track layer due to easy installation and maintenance. In November 2016, the Light Rail Days event which focuses on Scandinavian tram projects, took place in Bergen, providing an opportunity for many international and Nordic visitors to get to know Bybanen’s tram operations during the event.

Gunnar concluded: “Bybanen is receiving many visitors from many countries worldwide. We are pleased to share our experience and hope that other light-rail projects may enjoy the same popularity and same positive benefits to their communities.”

References:

- Authors: Alexej von Glasenapp (Business Development Manager Europe, PCM RAIL.ONE AG), Ryan Stolpmann (Segment Manager Urban Transportation, PCM RAIL.ONE AG) and Philipp Nachbaur (General Manager, RHOMBERG SERSA RAIL GROUP)

- Solveig Mathiesen, Project Manager Bybanen, presentation at Light Rail Day Bergen, 14.11.2016

- The PCM RAIL.ONE Group is an international manufacturer of concrete sleepers and track systems for urban transit and long-distance rail transportation. The Group also offers its expertise in the field of engineering and plant construction. One RAIL.ONE slab track solution is known under the RHEDA 2000® brand name. RHEDA CITY, a slab track solution for light-rail transit is a technological spin-off the RHEDA 2000® solution, with important track work installations all over Europe.

Related topics

Infrastructure Developments, Track Construction, Track/Infrastructure Maintenance & Engineering