Innovative engineering saves money on Liverpool railway tunnel upgrade

Posted: 12 October 2016 | | No comments yet

A cost effective rail engineering technique is being used to upgrade a Victorian railway tunnel leading to Liverpool Central station.

A cost effective rail engineering technique is being used to upgrade a Victorian railway tunnel leading to Liverpool Central station.

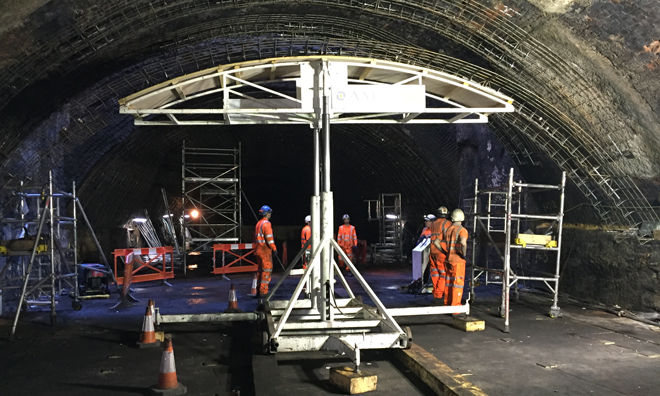

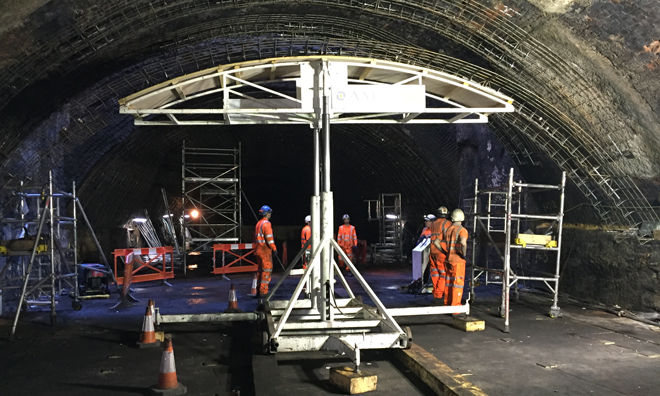

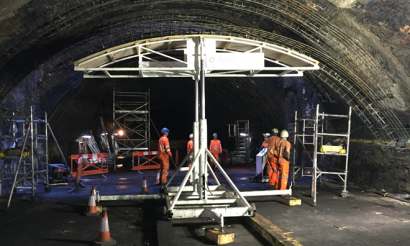

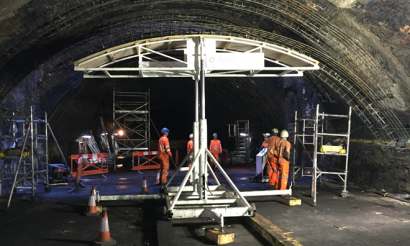

An innovative scaffolding method is currently being used to upgrade Liverpool Central tunnel helping Network Rail save £9.5m in costs and ensuring future services for Merseyside commuters.

New engineering method helps save £9.5m

By installing an access platform secured to the tunnel walls, 15m above track, engineers are able to apply a number of layers of water-sealing cement onto the tunnels curved ceiling while MerseyRail trains continue to run below. Concrete is applied by using a robotic arm which, according to Network Rail, is a much safer approach for the workforce as well as more cost-efficient approach. Once complete, the newly sealed tunnel ceiling will not need any further maintenance for more than a century.

Tunnel maintenance not needed for a century

Adrian Bullock, Project Manager at AMCO Rail, Network Rail’s contractor on this scheme, said: “We are doing 160 linear metres of tunnel line repair, putting a steelwork arch in with 300mm of concrete, which basically will see the roof become maintenance-free for the next 120 years. “Usually this work would cost £14m but doing it with this new system with a live operational rail underneath allows this work to do it for £4.5m. That’s a saving of £9.5m for taxpayers – all while allowing trains to keep running into Liverpool Central and avoiding disruption to the travelling public.”

Liverpool Central tunnel upgrade work is part of Network Rail’s multi-billion pound Railway Upgrade plan.