Rail freight: Breakthrough into the digital logistics ecosystem

Posted: 20 April 2018 | Fabian Ringwald, Gianpaolo Leccardi (SBB Cargo), Rahel Winkelmann (SBB Cargo) | No comments yet

The exchange of information is a critical success factor in supply chain management. Game changers such as Physical Internet, Internet of Things (IoT) and Automation lead to a consolidation of logistics networks.

The challenge for rail freight lies in securing the connectivity to a digital logistics ecosystem. The aim must be to become an essential part and, as explained by colleagues Fabian Ringwald, Gianpaolo Leccardi and Rahel Winkelmann, SBB Cargo has taken the first steps towards the future with innovations in automation and digital services.

The pursuit of efficiency blurs the boundaries between production, transport and the market due to global logistics. Data flows – the pulse of modern logistics – are replacing rigid system processes. Intelligently linked, they form the basis for a digital logistics ecosystem. The boundaries of individual participants and organisations become blurred, and visibility is called for in a holistic way. This transformation affects us all, especially the rail freight sector.

Full steam into standstill

With the invention of the steam engine, a new era began in the 18th century: Mechanical drive automated processes; production and transport of goods were revolutionised. In the era of Industry 1.0, the birth of the railways was an essential driver of the emerging modernity.

Followed by mass production (electricity; Industry 2.0) and with computers, the information age (Industry 3.0), the world continued to develop rapidly. The whole world? No! An industry populated by indomitable railroaders got overhauled: The freight train, a pioneer of Industry 1.0, had fallen asleep after its greatest success.

Long investment cycles in freight cars led to technological standstill for decades. Road logistics, with pragmatic and customer-oriented solutions, was ready to conquer the market as its main competitor. The digital transformation is widening the gap between railway and road logistics once again. Freight railways are faced with the enormous challenge of making the transition from Industry 1.0 to the digital world of Industry 4.0, ensuring its ability to connect towards digital logistics ecosystems.

Information: Core of modern logistic ecosystems

Global commodity flows are the backbone of our economies. Geographical distances between manufacturers and consumers have become less important. Value creation is globalised across all industries. The supply chain is the link between production and market. Standardised and affordable means of transport are the primary factor for ensuring an efficient connection.

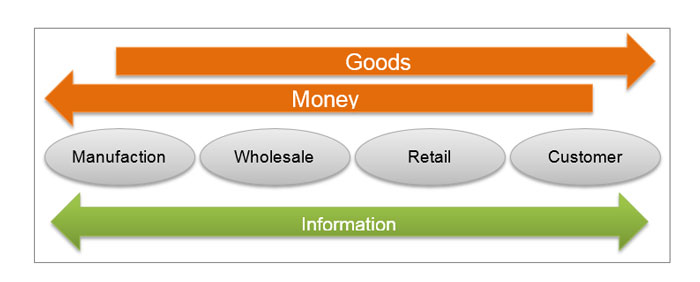

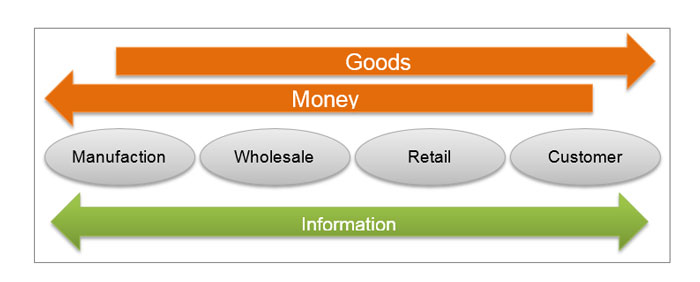

Supply chains consist of flows of goods and money, managed along the entire value chain. The flow of goods is based on the physical transport from receiving to delivery to customers. Transports move across borders, involving many participants. The physical flow is the most important component of a supply chain. Second is the flow of cash, where all financial movements are processed.

Supply chains function as networks where interaction of the participants is crucial for efficiency of individual chains and the entire network. Aiming for the global optimum is the reason why a third part of this network emerges: The flow of information forms the new fundament of the modern logistics ecosystem.

The three streams of a supply chain

With the age of digital logistics ecosystem ahead, the traditional idea of a supply chain with goods and money at the heart of value creation is extended. The supply chain as a network focuses on the exchange of information as a new success factor. Even now, that exchange is inefficient and considerably delayed. How does that system, based on its analogous strengths, manage this transition?

Analogue excellence is still key: Physical transport remains the primary raison d’être for every logistics ecosystem. Although excellence is very much present within the management of physical and financial flows, individual optimisation has reached its peak and offers little scope for diversification.

Approaches to optimise the flow of information exist, but are of younger origin. An incentive here is the challenge of the bullwhip effect1. These approaches must be effective across value-added stages. They are often not easily identifiable for individuals, but offer above-average optimisation potential. Other approaches were technical and produced exchange formats like UN/EDIFACT (ISO 9735) or EPCIS2. The optimisation of information flow has just started, developments fundamental to the creation of a digital logistics ecosystem are becoming visible. Based on data, logistic networks converge and information becomes the decisive factor for efficiency, setting the base for holistic Supply Chain Visibility3: Market participants trust each other to an extent where relevant information is (automatically) shared to react to downstream processes.

The transition from an analogue-physical to a digital logistics ecosystem involves efficient use of data and partnership-based trust. In the age of digitalisation, the combination of experience-based knowledge with intelligent algorithms is in demand for insights from data. Rarely both are available within individual companies. Hence, exchanging information across borders becomes a vital necessity. The path to a digital logistics ecosystem presupposes a clear paradigm shift in a rather sluggish industry. This change will benefit from trends that are already observable today.

‘Game changers’ shaping the future

The last disruptive development in logistics was the invention of the sea container. Others arose from continuous ideas for improvement – the effect was significant, but not revolutionary. The transition from the traditional logistics ecosystem to a digital one will not be possible solemnly by continuous improvement. ‘Game changers’ will evolve and play a disruptive role:

The Physical Internet4

The Physical Internet applies the principles of the digital internet towards logistics: The way in which goods are transported, stored and delivered corresponds to the principles of transporting data packages between servers. Optimisation happens overall on a consolidated basis. Goods are then transported in standardised, exchangeable transport containers, transportation stages follow uniform rules that are publicly known. The choice of the means of transport and route is determined by standardised parameters of dynamic routing algorithms. For the user (sender or recipient) of the Physical Internet, both remain transparent. In analogy to the transport of e-mail, participants are only interested in sending and receiving. The exact route a package travels in the network is irrelevant for value creation. The algorithm decides on the next best transport step towards the target, considering requirements such as speed, cost or functionality. This decision is made at each node and results in the optimal transport variant (mode, route) given the networks present status (availability, load).

Utilisation of providers is no longer optimised individually. In the Physical Internet, the flow of goods will be optimised by bundling resources, acting as complete system using standardised software. It is based on the principle of distributed logic. Individual nodes are not able to take over the system as a whole – another principle that underlies the internet and emerging blockchain technologies to prevent manipulation.

For most industries, logistic services are a means to an end rather than a core differentiator, yet participants try to compete there too, accepting overall inefficiencies. To resolve this, an early step towards a Physical Internet are emerging co-opetition models5. The conclusion here is a consolidation of participants serving similar functional and geographical target groups.

Internet of Things (IoT)6

While the Physical Internet focuses on the efficient use of networks by abstracting from individual participants, the Internet of Things (IoT) offers the technical basis for fine-grained, automated data collection of all actuators. Different objects are equipped with sensors and connected with the internet and thus amongst each other. In its essence, IoT is the digitisation of the physical world. The areas of application are manifold and range from sports bracelets and intelligent street lamps to merchandise tracking in production and delivery scenarios. Regardless of the area of application, smart objects all work according to the same principle. They record relevant information and exchange it directly with objects in the network. The aim is to make the world simpler, more comfortable, more intelligent and more efficient.

Connecting the IoT potential with the Physical Internet using a delivery container as an example: The container would communicate its weight, destination and estimated date / time of arrival. Routing nodes for which this data is relevant link it to additional information from the Physical Internet (availabilities, costs, constraints) to determine the optimal route. Once the delivery arrives, the container triggers an automatic invoicing process. IoT enables the exchange of information in a direct and immediate end-to-end way.

Besides the ubiquitous availability of relevant information, the disruptive approach lies in the potential elimination of central systems: IoT provides a wide range of information allowing the interaction between participants and objects that do not necessarily have to originate from a common (company) context.

Automation

Automation has been with us for decades: Advances in robotics and autonomous driving are present. Frequently the focus is on self-propelled vehicles and road traffic. But automation also offers considerable potential in the field of logistics: Self-propelled trains – or, as a first step, freight trains that are equipped with automated couplers7, reduce the complexity of planning. And in the field of road logistics, automatic loading and unloading of trucks using robotics with intelligent storage systems is close to reality.

The core of automation is the reduction of complexity and the increase of flexibility. In many cases, this means becoming independent of human labour and increasing safety by preventing accidents. It can be challenging to make this change bearable for society. In addition to the primary efficiency gains, the disruption here lies in the question of how demographics and changing job profiles can be sensibly combined. Our future logistics ecosystem with its economic relevance thrives in change by balancing the social benefits relative to individual needs.

Importance for freight railways and SBB Cargo

The world of logistics will change. You might see more potential in blockchain and machine learning than in the aforementioned ‘game changers’, but the central question remains – how can information be used across value-added stages? The answer is in the principle of networked information exchange and will impact freight railways. Freight railways will merge into holistically optimised and, above all, transparent networks. Individual services are unbundled by bundling data and standardised information exchange following the trend in logistics. The aim of freight railways must be to become interoperable as part of a global digital logistics ecosystem.

Despite all the euphoria for the future, there is little evidence of disruption today. However, SBB Cargo has already taken steps towards the future. First digital customer solutions were launched in the market under the label SBB Cargo Digital8. The focus lies on improving supply chain visibility and optimising processes.

SBB Cargo Digital – Mobile, visual scanner for the wagon ID

A mobile ‘Cargo Check-In’ brings the check-in process in single wagonload traffic from the back office to the ramp. Workers can report freight wagon directly to SBB Cargo for collection. The highlight is the scanner integrated into the app, which allows wagons to be identified fast. Here it was possible to shorten the process and eliminate sources of error thanks to a continuous flow of information.

‘Cargo View’ is used to keep an eye on the rail part of supply chains. A ‘track & trace’ function with dynamic arrival forecasting enables the ability to query shipments in real-time and react to deviations. For seamless connectivity to ERP and logistics systems, ‘Cargo API’ offers all information and data in the form of a modern interface for integration.

The goal of SBB Cargo Digital is to deliver information quickly and concisely per shipment. But in a dynamic environment, customer needs are volatile. To ensure that relevant information is made available, SBB Cargo has taken a new approach. Using agile principles, development has been in tight collaboration with customers going from selection of data and aggregations to meaningful presentation and a sustainable pricing model. Compared to previous solutions, SBB Cargo Digital is not a finalised product. The early market launch is based on the insight that digitisation is to be understood as process with the aim of being jointly prepared for potential disruptions.

SBB Cargo Digital – Supply Chain Visibility

The basis for these new digital services is the intelligent freight wagon from SBB Cargo. Smart sensors provide information about the condition of individual wagons, allowing for traceability and monitoring. Information such as temperature, humidity, vibration and position of the wagon are immediately available to customers, allowing for early intervention in case of deviations. The modern freight wagon from SBB Cargo will become the intelligent means of transport of the future and is already the rolling IoT, enabling the first step into a digital logistics ecosystem9.

References:

- Herlyn, Wilmjakob; ‘The Bullwhip Effect in Expanded Supply Chainsand the Concept of Cumulative Quantities’; epubli Verlag, Berlin, 2014, S. 513-528

- GS1 Standard; ‘EPC Information Services (EPCIS) Version 1.2 Specification’; 09/2016.

- Hulstijn, Joris et al; ‘Integrity of supply chain visibility: Linking information to the physical world’; Faculty of Technology, Policy and Management, Delft University of Technology, The Netherlands; 2012

- Montreuil, Benoit; ‘Towards a Physical Internet: Meeting the Global Logistics Sustainability Grand Challenge’; CIRRELT – Centre interuniversitaire de recherche sur les réseaux d’enterprise, la logistique et le transport, Université de Montréal, Canada; 01/2011

- Brandenburger, Adam; Nalebuff, Barry; ‘Co-Opetition: A Revolution Mindset That Combines Competition and Cooperation’; ISBN 0-385-47950-6 ; 1996

- Mattern, Friedemann; Floerkemeier, Christian. ‘From the Internet of Computers to the Internet of Things’; Distributed Systems Group, Institute for Pervasive Computing, ETH Zurich, Switzerland; 2010

- SBB Cargo; ‘Automatische Kupplung für den 5L-Demonstratorzug’

- SBB Cargo – Cargo Digital

- SBB Cargo; Automation und Innovation im Schienengüterverkehr der Schweiz

Biographies

Related topics

Big Data, Cargo, Freight & Heavy-Haul, Digitalisation, Internet of Things (IoT)