Health and safety at Crossrail: A lasting legacy

Posted: 2 August 2018 | Martin Brown - Crossrail | No comments yet

When presented with the prospect of implementing a health and safety strategy for a major project such as Crossrail, where do you start? Delivering the resultant Elizabeth line – due to open in December 2018 – entailed the construction of a new railway that stretches more than 60 miles from Reading and Heathrow in the west through central tunnels across to Shenfield and Abbey Wood in the east; building new tunnels and stations below the busy crowded streets of the UK’s capital. Ensuring the safety of all those working on this scale of civil engineering project is a monumental task, but one that Martin Brown, Health and Safety Director of Crossrail, tackled with great success. He spoke with Global Railway Review to explain how.

“We believe that everybody should go home safely and in good health at the end of a working day; nothing is more important than that,” begins Martin. “We began by making safety our number one core value, rather than a priority. Crossrail has five central values, but safety – which also includes ‘health’ in its scope – was a fundamental concept that ran through everything.” Martin explained that this negated the issue of questioning what the priority was at each stage of work; safety was always their first consideration.

Target Zero

Daily operations were underpinned by an approach that had been used on other projects, termed ‘Target Zero’ – the belief that a project can experience zero accidents.

The health and safety project translated Target Zero as a guiding principle that all harm is preventable; that all incidents – if you trace them back – can be prevented. Martin explained that a core part of their accident investigation activities was about continually testing that belief. “Generally speaking, when incidents have occurred, we see ways that they could have been prevented. We use these experiences as an opportunity to learn, because a key part of the project is to ensure that we learn and improve our practices along the way.”

The third facet of the Target Zero approach is acknowledging that ‘zero accidents’ can only be achieved through the cooperation of all partners, so it becomes high on the agendas of all parties involved.

“Much of this is written down in our Works Information,” explained Martin, “which sets out our requirements for Tier 1 contractors and their subcontractors – Tier 2 and Tier 3 contractors – to adhere to. We put several structures in place to help that work and perhaps the most important senior level structure was what we called our Safety and Health Leadership Team (SHELT).” Crossrail’s SHELT brought together several directors of Crossrail – such as the Programme Director, Delivery Director, Health and Safety Director – with the board directors of the joint ventures.

Joint ventures

The Crossrail project consisted of a series of joint ventures. In order to spread out the economic and programme risk, joint ventures were put together to do the tunnelling, stations and shafts, and certain other specialist system-wide contracts. Each of these had a board of directors whose members were part of SHELT. In this way the SHELT became a key programme body that enabled structured discussions about health and safety to take place, whilst giving a lot of access to the contractors regarding what Crossrail was thinking, and what they were thinking.

From Olympics to Crossrail: A tried a tested platform

Martin explained that the SHELT approach had been used on the 2012 Olympics project. “In fact, several individuals who joined our team also worked on the Olympics. We took a number of their systems that had been used successfully before and developed and refined it.” This approach of refining and improvement runs through the Crossrail approach to health and safety and influenced the way they monitored its application.

Keeping track

“We developed a Health and Safety Performance Index (HSPI),” explained Martin, “which initially had 13 elements to it, but which was cut down to six as the project developed. Some elements were leading indicators – such as carrying out inspection visits and leadership tours – and some were related to how they dealt with accidents, which were also considered leading indicators as they looked at how well they had managed the investigations and closeout activity.” Martin continued: “The HSPI also comprised lagging indicators in terms of performance. These included lost-time incidents, more serious RIDDOR incidents and high potential incidents (HPIs). We were able to show a reasonable relationship between the improvers in the HSPI and the improvements in health and safety over the lifetime of the project.”

Despite the HSPI not being a new phenomenon – contracting and operational firms both use them – the Crossrail version has proved very engaging to the managers and directors, as well as the staff themselves, because there were benefits on all sides. Crossrail recognised good performance of contractors, both as a whole and individuals.

Health and safety also played a key role in the selection of Crossrail’s contractors. “We continually referred back to Target Zero in our approach, making sure that contractors had the right health and safety records,” said Martin.

Safety was made the number one core value right from the start of the Crossrail project

Refinement

The project used another process called the Gateway Assessment, which formed a second part of the HSPI, regarding daily and monthly performance of teams and individuals. “It allowed contractors to suggest good performance ideas that would develop over time through collaboration between CRL (Crossrail Ltd) and the contractor,” explained Martin. “It was designed to encourage contractors to continually aim to improve – both their general performance and health and safety performance. They were audited against those suggestions, innovations and the new procedures they adopted. This entailed talking to people on site and the contractors giving presentations themselves.”

The results of the Gateway Assessment audits were shared with the other contractors, which helped to enhance development throughout the course of the project.

Keeping it fresh

The scale of work involved in Crossrail was monumental, so Martin explained that “keeping it fresh” was the main challenge throughout. The induction process was fundamental for all contractors involved on Crossrail – no company nor their staff came onto the project without having been formally inducted. However, given the duration of the project, “keeping the message fresh and consistent” was vitally important.

“We achieve that through daily supervision and by feeding back through our accident and investigation work and highlighting good practice,” explained Martin. “We also do it through daily engagement with those people out on site: the directors, senior managers, construction managers, and project managers. They’re all out on site communicating with people and reinforcing what good practice is. They listen to the concerns of workers regarding what’s important to their health and safety and they work to maintain this at all times.”

Harsh lessons

Another cause for reinforcing the importance of safety was sadly down to a fatal accident that occurred about half way through the project, when a section of sprayed concrete lining fell from the crown of the roof of a tunnel section. Important lessons were learned as a result.

“That one very tragic incident has had a lasting impact on everybody who worked on the project; we had set ourselves very clear goals to not have serious incidents, yet we encountered one so serious that it caused someone to lose their life.” The reverberation of the incident was widely felt: “There is no doubt that it did impact everybody from the Chief Executive down. The incident resulted in the contractor being prosecuted, but crucially, it reminded us why we care about health and safety and the importance of following the rules and procedures we put in place, in this case exclusion zones.”

Martin continued: “We made an important commitment (reinforced by this incident) that people should be kept away from areas in which people or machines were working overhead. If there is a possibility that people are working above or below you, an exclusion zone needs to be set up to keep people and plant and equipment apart. There is no doubt that this tragedy served as a harsh reminder of why we set the high standards we did, and why we maintained them.”

Crossrail’s safety legacy

Crossrail set out to not only achieve a zero-incident project with improved systems for ensuring good health and safety practice, but to also promote their learning legacy via specific channels.

Martin explained: “We set ourselves a goal to try to be better than the other large civil engineering projects around us – and for a long time we compared ourselves to the Olympics; a project with a very good record. We were able to show that we had an accident record that was better than the Olympics, just about all the way through (thus far).”

They also used the project to ascertain why large-scale engineering projects experience certain trends over their life-span.

“We wanted to understand why – particularly on large projects – there seems to be more of an accident problem at the start, which then falls and then a rise near the end of the project,” said Martin. “We discovered the importance of establishing the right safety culture early on and maintaining it through to the later stages when the smaller trades come on board.”

Stepping up

Every six months a week-long exercise called Stepping Up Week took place, which involved bringing in external speakers and various events held within the stations and tunnel, all focused on health and safety.

“We’ve carried out physical activities such as evacuation exercises and invited trade suppliers to demonstrate how to use the equipment properly,” explained Martin. However, a key benefit of Stepping Up Week has been the ability to effectively communicate our core concerns, with mental health and resilience issues being a crucial element of working on the Crossrail Project. We have made excellent use of speakers to communicate their personal experience of dealing with such challenges.

Martin said: “Perhaps the most effective speaker on this subject was the British ex-boxing World Champion, Frank Bruno, who spoke about his own mental ill health and how he learnt to deal with it. Individuals who have either had accidents themselves or whose loved-ones have, have also shared their experiences and this has been a very impactful means of communicating the subject to project workers.”

Keen to point out as much when things go right, Martin told that this information has been effectively relayed, too: “We have also aimed to put out as much about good practice as when things have gone wrong. Research has shown that documents have been effective on this subject and we need to do even more to build on what can be achieved by highlighting the positives in the future.”

Safety is high on the agendas of all construction parties involved in Crossrail

Martin is keen to share the many processes that have formed incremental facets of the safety culture at Crossrail, highlighting useful learning exercises as well as when accidents actually occur and the evolved practices that proved essential in day-to-day operations: “We have concentrated on something that we call The Point of Work Briefing; at the start of every shift people are made aware of the possible risks they’ll encounter in the areas that they’re working in, and encouraged to find positive ways of controlling these risks. This really helped to raise awareness.”

Of particular satisfaction have been the legacy elements that could not have been foreseen at the start of the project. Throughout the duration of Crossrail, work was carried out to help cyclists and heavy goods vehicles (HGV) appreciate the risks posed by each other to each other. “We worked with the police to get the cyclists to understand the risks of cycling around HGVs in a programme called Exchanging Places,” explained Martin. “Though not a visible outcome of Crossrail per se, we feel this was a very worthwhile project that potentially prevented many accidents from occurring. We are sure this has really made a difference.”

Continual improvement

Martin promotes the existence of a Learning Legacy website that highlights those activities that worked well in all the lectures and meetings he has with external stakeholders. “We already know that this website has been impactful to others because they’ve approached us from projects all over the world – New Zealand, Australia, USA, South America and Europe – to ask us what we’ve learnt and how we’ve learnt it. Via telephone and video conferences and meetings we’ve been able to share our experience. We want others to refine what we’ve learned so that things can continue to improve in the future.”

Improved healthy working practices have also evolved thanks to the work with silica and silica dust. Martin explained: “Several innovative machines were developed in order to reduce the dust exposure problem; this meant that the drilling was carried out by new machines rather than individuals, which had several key benefits: It prevented people being exposed to the dust and the work was carried out more quickly and with greater precision.”

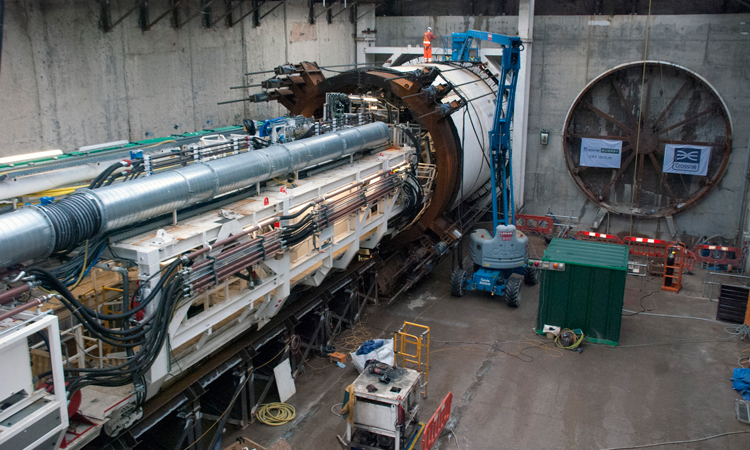

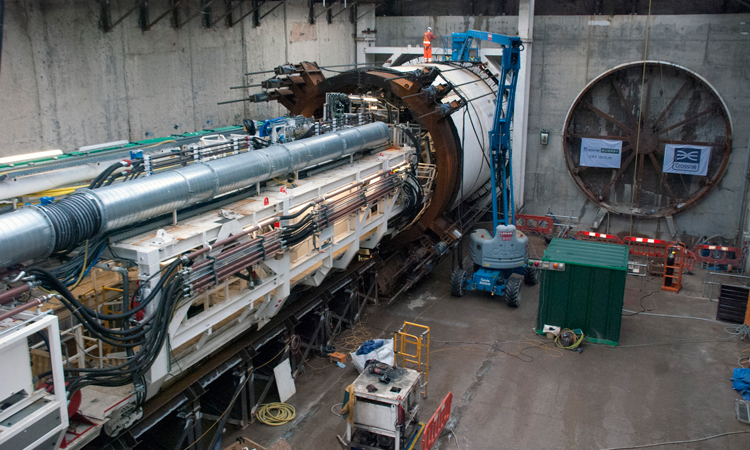

Other techniques and devices were developed to deal with challenges that arose; including utilising a special train on which to mix the concrete for direct delivery into the tunnel, and a new device that delivered and erected the platform screen doors – all taking people away from higher risk areas.

“Basically, we developed several devices and machines that increased our productivity and the quality of our output but kept people safe and protected health. This also enabled consistency and reduced fatigue.” Martin said.

An evolving legacy beyond H&S

Large projects such as Crossrail can make a difference on many aspects that may not be obviously linked to health and safety. These include such benefits as the large apprentice programme that has seen over 1,000 apprentices work on the programme, the HGVs and cycling work, the major environment programme that saw a large new nature reserve built in the Thames estuary using the spoil from the tunnelling work, the art programme that can help to enrich the lives of Londoners and the major improvements in the public realm. They can also improve awareness and methods of dealing with mental health, which wasn’t on the agenda at the start of the project but became progressively important as the project went on. Martin explained: “The same is true of cyber-security, which we were not thinking about at the start of the programme, but grew to be an important facet of how it developed. Large projects give you the opportunity to really make a difference and I think we have done that.”

Biography