How to implement efficient railway maintenance through digitalisation

ABOUT THIS WEBINAR:

Efficient rolling stock maintenance is a key success factor to ensure performance, availability and reliability of service.

For years, classic operation and repetitive maintenance activities have been the norm, but today digitalisation and the emergence of the Internet of Things (IoT) widens the range of possibilities to achieve a higher level of excellence in services and asset management.

With this in mind, Alstom has created HealthHubTM – an innovative approach to condition-based and predictive maintenance for rolling stock, infrastructure and signalling. This integrated decision-support range of tools (sensors, cameras, lasers, dataloggers etc.) continuously monitors the state of the assets to prevent failures, questioning the standard execution of maintenance activities.

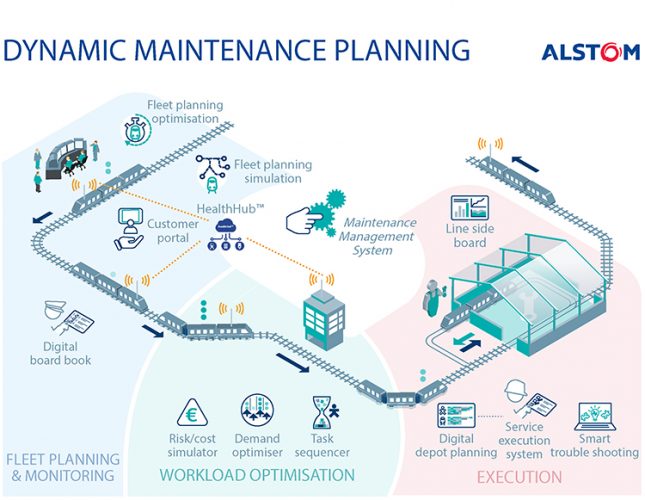

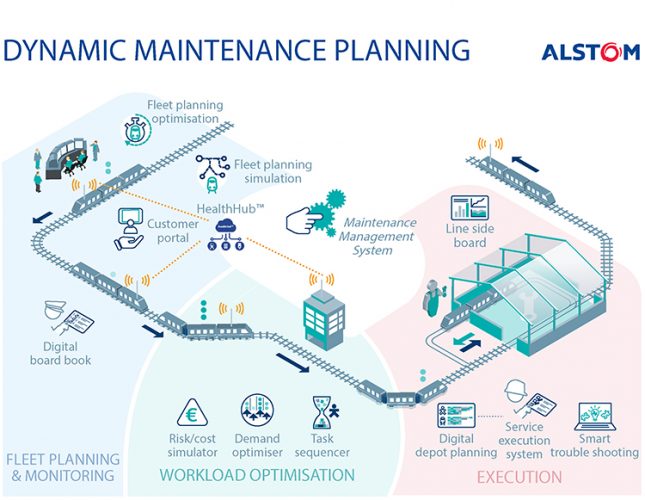

To further build on the success of HealthHubTM and turn the collected data into action, Alstom has now launched Dynamic Maintenance Planning – a new solution that allows a more responsive, flexible and fluid execution of maintenance activities.

Furthermore, it delivers value during the operation and at each step of the maintenance plan, building seamless interactions between operations and maintenance.

The key benefits of Dynamic Maintenance Planning are:

- Automated information flow

- Visibility and traceability of activities

- Avoiding over maintenance

- Optimised operations

- Increased industrial execution efficiency.

KEY LEARNING POINTS:

- Explore the impact of advanced health and monitoring systems to benefit maintenance activities of the railway industry

- Review the key steps and how to execute the process by assessing how digitalisation can bring optimisation and to identify the clear benefits of performing maintenance tasks

- Understand the key success factors to efficiently implement this type of approach.

Register

Register to watch this on-demand webinar

Speakers

KEYNOTE SPEAKERS:

Dynamic Maintenance Planning programme.

Related topics

Big Data, Digitalisation, Infrastructure Developments, Rolling Stock Maintenance, Technology & Software