Managing wheelset life

Posted: 8 July 2024 | Keith Mack | No comments yet

Keith Mack, Chair of UK Wheelset Management Group, explores how technology enabled predictive maintenance is effectively elongating the lifecycle of the wheelset.

Wheelsets are the most ‘safety critical’ part of a rail vehicle, also usually the biggest cost throughout vehicle life resulting from many wheelset replacements. It follows then, to maximise wheelset life that the most important consideration is maintenance. Train manufacturers, maintainers, overhaulers, passenger and freight operators are actively improving safety, controlling wheelset costs and as a result, total vehicle life cycle costs. In general, wheelsets are overhauled as part of a bogie overhaul (being the most convenient time to do this), however, this is not the only strategy and other methods to change single wheelsets when worn or damaged are also used.

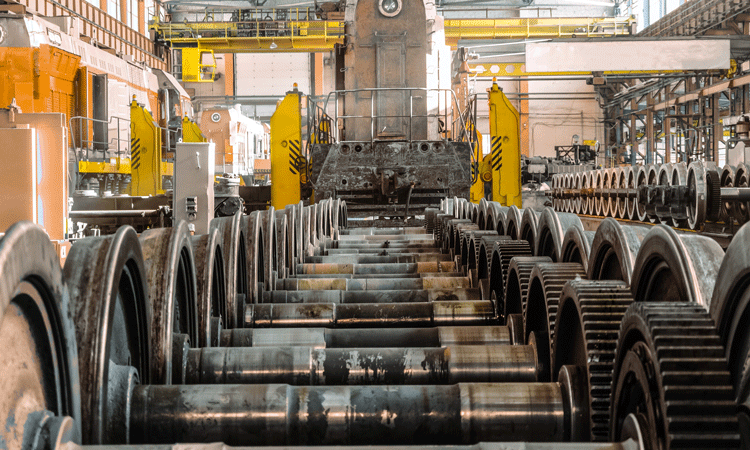

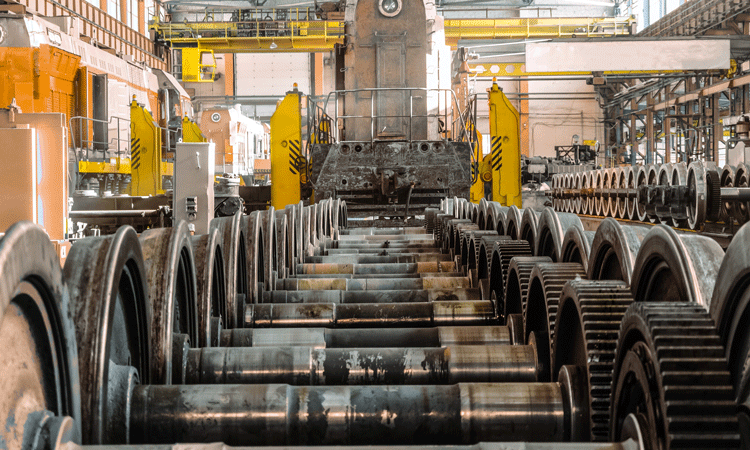

Wheelsets for use after overhaul

The wheelset as an assembly performs a number of functions. Firstly, through the axle bearings, it supports the load of the vehicle enabling extremely low friction movement. It is important that the axle loading is correctly set up to prevent wheel unloading in service. Secondly, to steer the vehicle on the track geometry in a safe manner. Thirdly, to provide traction through an axle mounted drive to the rail. The fourth is, disc or tread braking to slow the vehicle through the transfer of heat energy. Finally, the connection to the bogie through the radial arm, primary suspension and if an electric vehicle, the axle end earth return.

Wheelsets have a tough life and suffer from several types of damage such as flats, cavities, wheelslip/slide damage, scoring, impact and general wear. It is important to ensure that flange height and thickness are kept within the specified limits for the respective profile type as excessive flange wear provides unsafe conditions and risk of derailment. Several times throughout wheelset life, the tread can be restored when needed by reprofiling until the smallest diameter is reached.

Traditionally, wheel life was constrained by the maximum life of axle bearings and wheels therefore remained operational within these limits. However, axle bearing technology, advanced lubricants, fitment improvements and prevention of contaminant ingress have allowed considerable extension to bearing life, hence the opportunity now exists to make wheels last longer to match this.

Wheelslide Protection Systems (WSP) are becoming more advanced and effective. They are fundamental in preventing wheel damage, but can only remain effective if they correctly detect slide early and react quickly. To achieve this, WSP systems need to be well maintained.

Improved measuring equipment and automated inspection systems are now in use, providing excellent quality images while recording correct information and thus enabling improved decision making.

Modern vehicles are fitted with wheel flange lubrication, these may be either graphite sticks, or lubricants projected onto the wheel flange.

There are other issues that can affect wheelset life, including an overheating axle bearing, a brake not fully released, transmission failure or a locked wheel.

Despite all of this, the biggest challenge is Rolling Contact Fatigue (RCF). This occurs when the wheel tread is subjected to cyclic, localised, rolling and sliding contact (normal running). In the tread contact area, high loads lead to sub‑surface cracking, shelling and if this abnormal condition continues, the surface degrades further with material coming loose and forming large deep cavities. These cavities, each time the wheel rotates, generate considerable speed dependent, high impact point load forces on the rail surface, in addition to the negative effect on ride quality.

Shelling and cavities

In GB rail, since around 2006, RCF has become a significant issue on both wheels and rails. There has been much research into this where the outcome has shown a number of reasons.

Firstly, there is a known link between RCF and how wheelsets negotiate curves, and the rail steel grade in use. Secondly, it is also known that maintenance intervals have increased considerably on older fleets, likely due to maintenance activities delivering acceptable wheel wear, damage and performance. Lastly, on new fleets with considerably increased wheel loads, the system integration between primary suspension, yaw stiffness and profile selection has not always been optimised.

Results of this research although published, have not really been widely understood and converted by maintainers into extended mileages.

The preliminary stages of RCF are sub-surface and are not visible on the tread, although may be evident using suitable Non-Destructive Testing (NDT). However, this is a specialist procedure, is expensive and not commonly used.

The most effective means to identify early RCF is using on-board fitted acoustic monitoring equipment. This checks a known ‘acoustic signature’ from a new wheel tread and shows changes as mileage increases. When parameters consistent with known early RCF are reached, action can be conveniently scheduled to reprofile wheels with minimum material removal. It is also possible to use line side acoustic monitoring equipment, but this is dependent on operating over the site and having arrangements in place with a third party for data capture. The benefits of early detection are often limited, not by available data but by wheel lathe location, availability and ability.

Managing RCF is less effective by increasing running miles and waiting until RCF becomes visible as cracking. Further operation increases the cracks and cavities are formed. This leads to noise and vibration inside the vehicle, high impact loads on the rail and considerable material removal at wheel reprofiling.

Rolling Contact Fatigue- visible cracking

Again, on-board monitoring equipment can trend the degradation as the mileage increases until such time that either reprofiling is planned, or, it has exceeded safe limits and is beyond reprofiling and needs a wheelset change.

Other ways to manage RCF include optimising the suspension set up and wheel profile choice.

Another option is to use one of the available advanced wheel steels such as Lucchini Superlos® however, fitment of these is ‘application specific’ and do not always provide the promised benefits as they are also affected by other factors, including the wheelset position in the vehicle or train.

The wheelset Engineer can only understand the ideal mileage to schedule reprofiling, by analysing the data from on-board systems, maintenance inspection and measurement. It is particularly important that wheel lathe operators are suitably trained in understanding and managing RCF. On the wheel lathe before reprofiling, a complete set of measurements and visible damage must be recorded. The amount of material removed to clear any visible cracks must also be carefully recorded. On the GB rail network, it is also possible to use ‘Economic Tyre Turning’ for defined wheel profiles. These are subsidiary hybrid profiles, specifically created following research, with ‘thinner’ flange dimensions between new and worn.

Managing wheelset life when driven by vehicle availability does not generally provide the means to operate a wheelset and achieve its full mileage life potential, however using all the data available and acting timely, will make a difference with a positive impact to everyone.

When taking any decisions relating to changes to maintenance practices, and the management of wheelsets, ‘safety’ must be the first and major consideration.

Keith Mack started work on the railways as a mechanical apprentice at the Craigentinny Maintenance Depot in Edinburgh in 1978, now in his 46th year. He has worked on all aspects of Rolling Stock maintenance from basic servicing to design, operations and standards, through this he has a sound knowledge of all vehicle systems, their interaction and specialist knowledge of wheels and axle bearings. He is currently the Chair of the UK Wheelset Management Group.