Digital track monitoring: Rectifying faults to keep trains moving

Posted: 20 April 2022 | Bane NOR | No comments yet

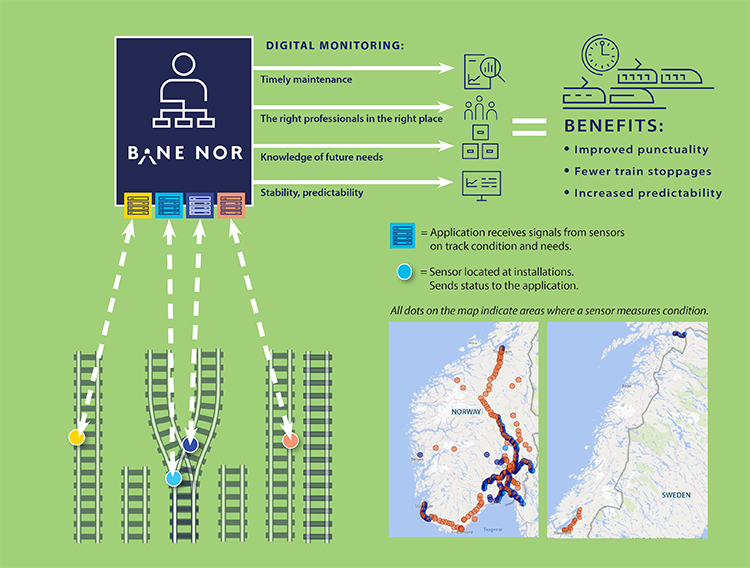

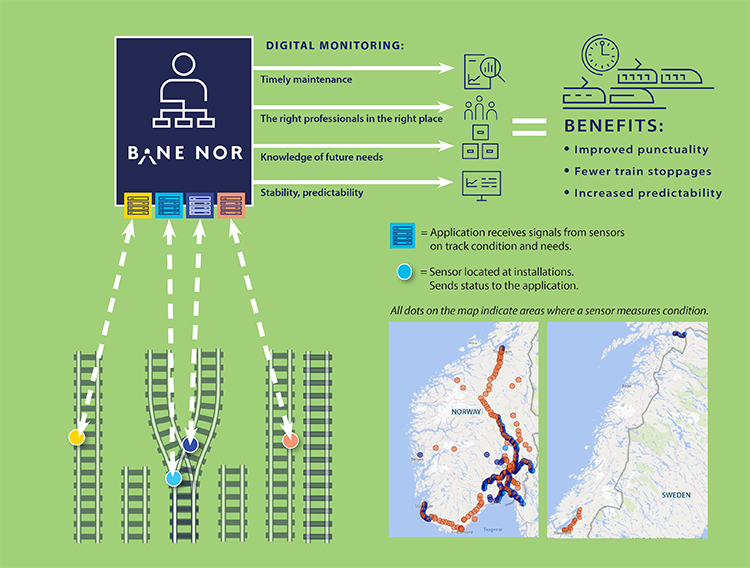

A new digital track monitoring system has been launched by Bane NOR’s ICT department in the form of an app that will signal to operators the need to rectify faults and what measures need to be taken, all before the issue results in train stoppages.

The app is constantly undergoing development and is being implemented on an ongoing basis. This work is taking place in close collaboration with the Bane NOR departments, such as track and traffic, that need new technological solutions.

“When we felt that off-the-shelf systems failed to meet our needs, we started developing our own track monitoring system which has now developed into a track monitoring app,” Kristine Tveit, Bane NOR’s ICT Lead for this project, said. “The development work is progressing smoothly, with the ICT department receiving feedback on its needs. We develop both the design and solution in collaboration with the railway organisations, among others.”

Sverre Kjenne, EVP, Operations and Technology, Bane NOR

How sensor monitoring works

Sensor data is sent by track components and systems where trains operate. This data provides information on the condition of the tracks and the need for maintenance and fault rectification. It also provides the basis for the maintenance programme that Bane NOR’s technical department is responsible for. This means that the timing of the maintenance is determined by the condition of the tracks and actual need. Measures can be implemented when the monitoring system indicates that they are needed; not based on fixed schedules.

We are at the centre of some very exciting technological developments in the field of data-driven maintenance.

The sensor data insights are displayed in the track monitoring app which is used daily by monitors in the technical department. They also assist the railway manager with root cause analyses, and similar, based on information obtained from the app. In addition, the railway manager organisation can use the app to gain permission and to follow up on the maintenance providers.

A new and smarter way of working

Kristine Tveit, ICT Lead, Bane NOR

Credit: Marianne Henriksen/Bane NOR

Sverre Kjenne, EVP of Operations and Technology at Bane NOR, is a true tech optimist and an enthusiastic driver behind Bane NOR digitalisation and the increasing use of innovative solutions. He is crystal clear on new technological solutions being essential when it comes to resolving the ever-changing challenges associated with growing numbers of departures and the associated increase in wear on the rail network. At the same time, he believes that there is plenty to be gained by combining new technology with older infrastructure.

“The track monitoring app develops in line with our needs and is implemented on an ongoing basis,” Sverre said. “This work will be very important to the future of the operation and maintenance of tracks and systems used by trains. We can stay one step ahead and prevent faults before they arise. This offers us a new way of working and helps us to avoid train stoppages and delays in the future. We call it Smart maintenance.”

We are at the centre of some very exciting technological developments in the field of data-driven maintenance. Right now, we are working to develop, improve, and commission this system across more parts of the country. This will allow us to achieve our objective of being at the forefront of developments, correcting any faults before they arise, and preventing train traffic stoppages.”

Sverre continued: “The Norwegian railway system will continue to be a blend of old a new for many years to come. It takes a very long time to update everything, and even though much of the railway network is older, it remains largely robust. We constantly need to work to get as much railway as possible for the money and target our efforts where they are most needed. Consequently, the solution often lies in equipping the traditional railway with new technology. This is why we are incorporating sensor technology, which enables us to monitor and improve the lines in a ground-breaking way.”

The sparring partner Microsoft

Bane NOR collaborates with Microsoft to study how data can serve as the basis for smarter and more proactive maintenance.

Bendik Wærp, Head of the Oslo signalling department, explains and gives a tour of the relay room.

Credit: Marianne Henriksen/Bane NOR

“We are pleased that the collaboration with Bane NOR resulted in Smart maintenance, and excited to act as a sparring partner to a forward-looking organisation such as Bane NOR as they work to develop Norwegian railways through the use of data,” Atle Spilde, Director Public Sector at Microsoft Norway, said.

Optimises maintenance

Cloud technology, smarter use of the data collected, and increased use of sensors has allowed Bane NOR to make better and more targeted decisions.

Mats Resaland, Data and Analysis Advisor at Microsoft Norway, is impressed by how Bane NOR has been able to use new technology and trial new solutions: “Cloud technology, smarter use of the data collected, and increased use of sensors has allowed Bane NOR to make better and more targeted decisions. By leveraging the opportunities provided by technology, they have been able to optimise maintenance of the Norwegian rail network.”

To find out about how Oslo railway manager Espen Kragelund is seeing the results of the app’s development, click here.

Related topics

Digitalisation, Operational Performance, Safety, Technology & Software, Track/Infrastructure Maintenance & Engineering

Related organisations

Related regions

Related people

Atle Spilde, Bendik Wærp, Kristine Tveit, Mats Resaland, Sverre Kjenne