FACILITIES SERVICES: expert for maintenance and renewal

Posted: 5 April 2010 | | No comments yet

Following the merger of the two companies ÖBB-Infrastruktur Bau AG and ÖBB-Infrastruktur Betrieb AG into ÖBB-Infrastruktur AG on 3 October 2009, the two divisions Construction and Maintenance and INFRA.service were also consolidated with effect from 1 January 2010 (see Figure 1).

Following the merger of the two companies ÖBB-Infrastruktur Bau AG and ÖBB-Infrastruktur Betrieb AG into ÖBB-Infrastruktur AG on 3 October 2009, the two divisions Construction and Maintenance and INFRA.service were also consolidated with effect from 1 January 2010 (see Figure 1).

Following the merger of the two companies ÖBB-Infrastruktur Bau AG and ÖBB-Infrastruktur Betrieb AG into ÖBB-Infrastruktur AG on 3 October 2009, the two divisions Construction and Maintenance and INFRA.service were also consolidated with effect from 1 January 2010 (see Figure 1).

Synergies through merger

In the medium to long-term, it will be possible to realise many synergy effects through this merger into FACILITIES SERVICES. There is great potential for optimisation through the streamlining of interfaces, the use of resources as well as the integrated route- and facilityrelated control. In detail, the following synergies can be exploited as a result of the merger into FACILITIES SERVICES:

- Consolidation of overhead functions

- Joint use of movable scotch blocks (maintenance window)

- Simplification of order process

- Optimisation of work processes

- Joint resource utilisation control

Service provider for facilities availability

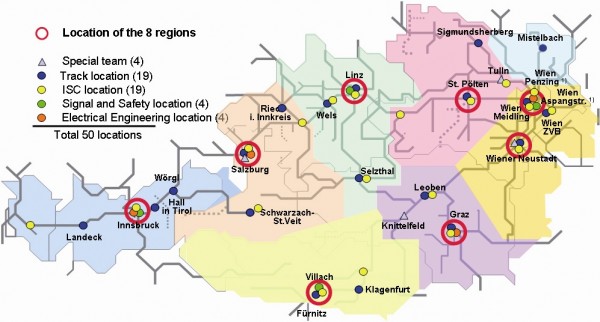

With approximately 5,600 employees, FACILITIES SERVICES is the largest division of ÖBB-Infrastruktur AG. The division is structured as a territorial organisation, consisting of eight regions divided into a total of 50 locations. FACILITIES SERVICES is the reliable partner along the entire route. On the one hand, the division, as a general contractor, is responsible for inspection, maintenance and breakdown repairs and, on the other hand, it is also active as a contractor for schedulable maintenance, renewal (‘beneath the rolling wheel’) as well as in the definition of tasks for new construction projects. The division’s duties also include work to ensure free passage through routes and train paths as well as the provision of other railway-specific services.

Using a capacity management system, approximately 4,200 operatively active employees from the specialist fields of Track (about 2,700 employees), Signal and Safety Technology (more than 800 employees) and Electrical Engineering (about 670 employees) are deployed daily to ensure the highest quality route availability.

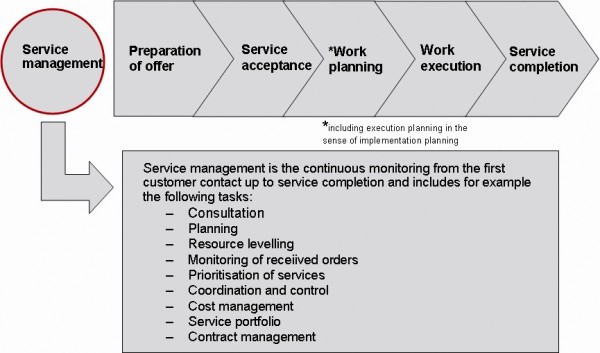

The core process in service management, which all core services undergo, includes all steps from the preparation of offers, the service acceptance and work planning to service completion (see Figure 2).

FACILITIES SERVICES keeps the following facilities available along the route:

- 11,000km of track, of which 8,200km is electrified

- 16,000 point switches, of which 10,800 with remote control

- 53,000 signals

- 6,630 bridges and viaducts

- 277 tunnels and galleries

- 5,553 railway crossings

- Approximately 33,000 insulated rail joints

To ensure the availability of facilities, FACILITIES SERVICES is structured (see Figure 3) in a territorial organisation with eight regions, 19 Infra-service Centres (ISC), 31 locations (of which four are special teams, 19 Track locations, four Signal and Safety Technology locations and four Electrical Engineering locations).

The core business of the division comprises inspection, maintenance, breakdown repairs and short-term maintenance with uninterrupted railway operation (‘beneath the rolling wheel’). Thereby, FACILITIES SERVICES acts as general contractor on behalf of the Route and Railway Station Management Division and takes care of the control, resource planning, material and machine logistics coordination, implementation and service accounting.

In addition, FACILITIES SERVICES offers services for an optimised resource control (manpower, material, and machines) for schedulable maintenance and renewal as well as training and know-how protection.

Infra.service Centre

With up to 180 employees, the ISCs works interdisciplinarily as general contractor for inspection, maintenance, breakdown repairs and short-term maintenance. The main tasks, however, are in the fields of inspection, maintenance and breakdown repairs. The ISC head has the disciplinary responsibility, whereas the technical responsibility of the individual trades lies with the Facilities Manager with up to 60 employees. The Resource Planner works hand-in-hand with the Facilities Manager and is in charge of resource control. This is made in close coordination between the specialist fields and the region’s service management. Response times (service level agreement (SLA) times) are provided for breakdown repairs. This is the period of time within which repair works of the breakdown must be commenced. The SLA times are different for the different specialist fields. They are between 30 minutes (for Signal and Safety Technology) and 90 minutes (for other specialist fields) during standby time.

Use of high-tech equipment

Apart from strong human resources, several railway construction machines are required for the performance of the maintenance and construction works, which meet the state-ofthe- art requirements and are available on call from sub suppliers on the basis of framework agreements. These include track construction and large construction machines such as for example high-throughput track laying and relaying machines, excavators, rail-borne cleaning machines and gantry cranes. Thus, FACILITIES SERVICES is capable to handle the most extensive construction works in the track area using high-tech equipment. FACILITIES SERVICES also leases special rail-borne vehicles such as track maintenance vehicles (54 units), motorised railway scaffold vehicles (71 units), motorised railway vehicles (62 units), snow ploughs for winter services (12 units) through Rail Equipment, a subsidiary of ÖBBInfrastruktur AG. Also flat, material transport, living and workshop as well as ballast wagons are provided by Rail Equipment. In addition, there are approximately 2,000 motor vehicles in the division to ensure that the agreed response times (SLA) can be met and to make material deliveries.

Strong logistics & disposal

The business unit Supply and Disposal/Railway Components with its 640 employees organises the logistics and goods supply for most of ÖBB-Infrastruktur AG, from the requirements analysis to scheduling, procurement, goods receipt, storage, picking, dispatch and transport. Other activities include the recycling and utilisation of track construction materials such as, for example, rail welding, reprofiling, sorting, sale and disposal. In 2009, 1.1 million tonnes of ballast was provided and a total of 160,000 running metres of tracks delivered.

The service portfolio in the area of Railway Components essentially includes the maintenance, repair, breakdown repairs and new construction of railway-specific components for the fields of Signal and Safety Technology, Electrical Engineering as well as Track.

Phönix and Aura

All order and execution data are recorded with a uniform recording system in the database system, Phönix. In addition, the planning software, Aura, is used as a basis for assignment control with the respective deadlines and intervals for maintenance and inspection works. In particular, the assessment including assessment number is stored in the programme on the basis of the resulting feedback of the pending measures and thus is retrievable and attestable at any time.

Further technological development

ÖBB-Infrastruktur AG is currently working on a concept for digital inclusion of the inspection data on site for the mobile condition identification of the facilities. In close coordination with the Route and Railway Station Management Dvision, low-maintenance forms of track construction are undergoing further development. Heat-treated rails contribute to the reduction of rolling contact fatigue damage (head checks). The strong horizontal forces in curved tracks put a high strain on the rail fastening elements. For this reason, new rail clamps that have shown a positive long-term behaviour were tested and are now regularly used in narrow track curves. The high number of narrow curves in the tracks requires testing the long-term behaviour of rubber rail pads (between rail and sleeper). The result was a positive influence on the reduction of corrugation. Also the use of (synthetic) sleeper soles to reduce ballast contact forces is pushed.

Partner and general contractor for Route and Railway Station Management Division

The Route and Railway Station Management Division is the key contact and ordering customer for FACILITIES SERVICES. As representative of the owner, the Route and Railway Station Management Division carries the responsibility for the facilities and commissions the division FACILITIES SERVICES – usually in the role of general contractor – with the execution of the required works. With its marked area-wide presence and the detailed knowledge of the facilities and locations, FACILITIES SERVICES is the competent and reliable partner for the maintenance of railway facilities. For the year 2010, FACILITIES SERVICES has already been commissioned with services worth approximately €600 million, of which €275 million for the renewal of facilities. In addition, the expertise and recommendation of FACILITIES SERVICES are an important basis for the maintenance programmes of the Route and Railway Station Management Division that uses these analyses for developments, the prioritisation of projects and the arrangement of financing.