Innovative engineering saves money on Liverpool railway tunnel upgrade

Posted: 12 October 2016 | | No comments yet

A cost effective rail engineering technique is being used to upgrade a Victorian railway tunnel leading to Liverpool Central station.

A cost effective rail engineering technique is being used to upgrade a Victorian railway tunnel leading to Liverpool Central station.

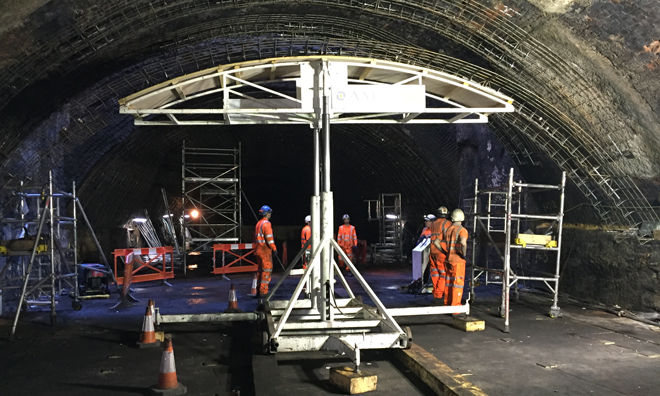

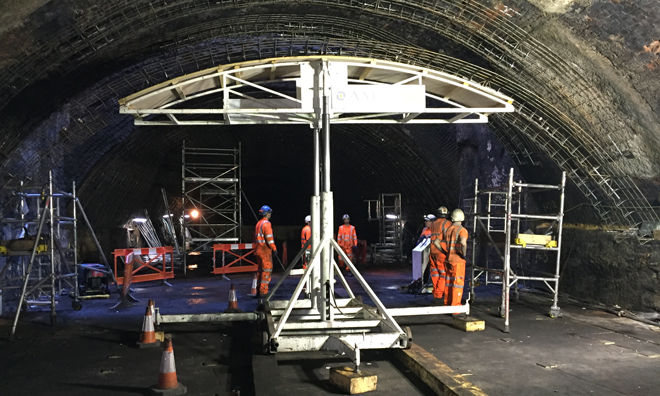

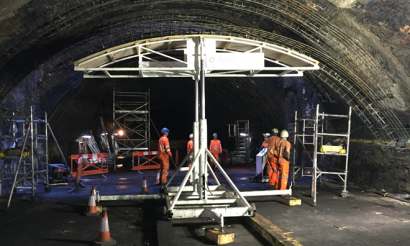

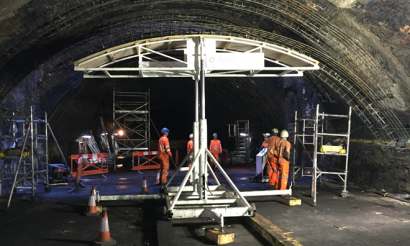

An innovative scaffolding method is currently being used to upgrade Liverpool Central tunnel helping Network Rail save £9.5m in costs and ensuring future services for Merseyside commuters.

New engineering method helps save £9.5m

By installing an access platform secured to the tunnel walls, 15m above track, engineers are able to apply a number of layers of water-sealing cement onto the tunnels curved ceiling while MerseyRail trains continue to run below. Concrete is applied by using a robotic arm which, according to Network Rail, is a much safer approach for the workforce as well as more cost-efficient approach. Once complete, the newly sealed tunnel ceiling will not need any further maintenance for more than a century.

Tunnel maintenance not needed for a century

Adrian Bullock, Project Manager at AMCO Rail, Network Rail’s contractor on this scheme, said: “We are doing 160 linear metres of tunnel line repair, putting a steelwork arch in with 300mm of concrete, which basically will see the roof become maintenance-free for the next 120 years. “Usually this work would cost £14m but doing it with this new system with a live operational rail underneath allows this work to do it for £4.5m. That’s a saving of £9.5m for taxpayers – all while allowing trains to keep running into Liverpool Central and avoiding disruption to the travelling public.”

Liverpool Central tunnel upgrade work is part of Network Rail’s multi-billion pound Railway Upgrade plan.

Global Railway Review Autumn/ Winter Issue 2025

Welcome to 2025’s Autumn/ Winter issue of Global Railway Review!

The dynamism of our sector has never been more apparent, driven by technological leaps, evolving societal demands, and an urgent global imperative for sustainable solutions.

>>> Read the issue in full now! <<<