Siemens’ AI powered Nanjing factory named World Economic Forum global lighthouse

Posted: 26 January 2026 | Gabriel Higgins | No comments yet

Siemens’ Nanjing plant earns World Economic Forum Lighthouse Factory status for AI-powered operations, digital twins and efficiency gains, cutting time-to-market by 33 percent.

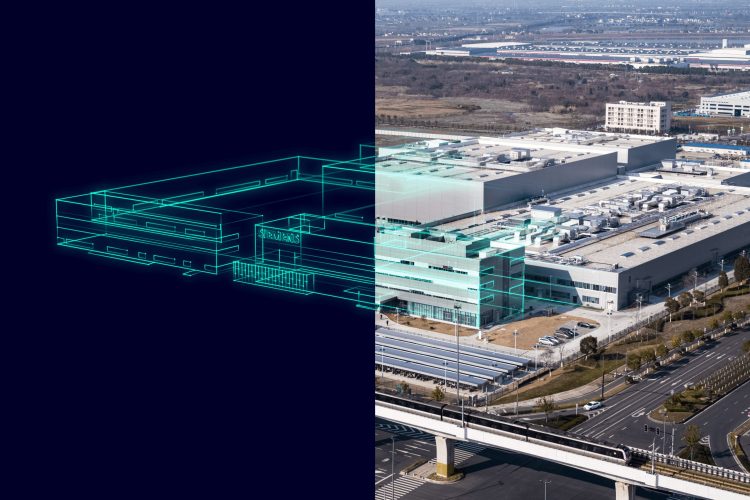

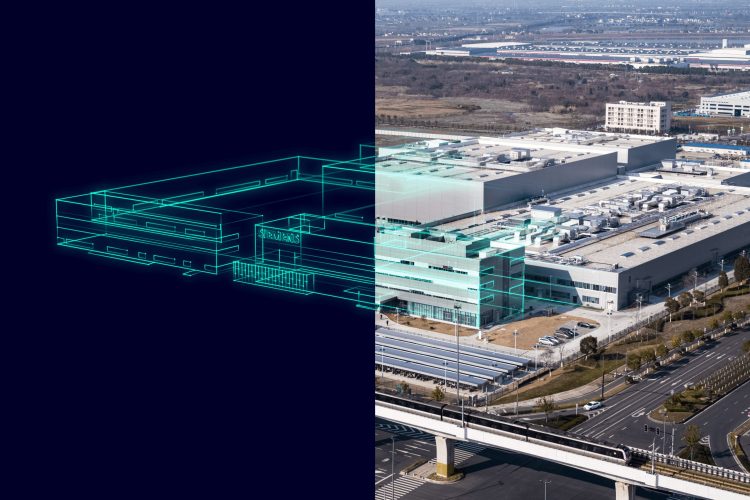

Credit: Siemens

Siemens’ Nanjing factory in China has been named a Lighthouse Factory by the World Economic Forum (WEF), joining the WEF’s Global Lighthouse Network of leading manufacturing sites worldwide. The facility, recognised in the productivity category, was honoured for exceptional performance in cost, quality and operational efficiency through continuous digital transformation and AI-driven manufacturing.

The Nanjing plant is the first “Digital Native Factory” Siemens has built entirely with a digital-first approach. Every part of the factory was designed, tested and optimised virtually before construction began. Cedrik Neike, Member of the Managing Board of Siemens AG and CEO Digital Industries, explained that this approach enabled faster construction under pandemic constraints, outstanding cost efficiency and flexible operations. “By combining global manufacturing expertise with local insight, we continuously optimise every part of the operation,” he said.

This factory is the fifth Siemens site to achieve Lighthouse status, following Amberg, Erlangen and Fürth in Germany, and Chengdu in China. The WEF highlighted improvements in asset utilisation, worker enablement and resource management.

Facing increasingly varied customer orders and shrinking delivery windows from 45 days to ten, the Nanjing site overhauled its production processes. Siemens deployed more than 50 AI applications, end-to-end digital twins, modular automation and manufacturing operations management systems to meet high-variety, low-volume demands.

The results are striking. Lead times fell by 78 percent, time-to-market dropped by 33 percent and productivity increased by 14 percent compared with 2022. Field failures fell 46 percent, while direct and energy-related carbon emissions decreased by 28 percent.

Spanning 73,000 square metres, the Nanjing facility is Siemens’ largest research and production centre for high-performance controls for machine tools, drives and electric motors outside Germany. It exemplifies the integration of digitalisation and sustainability, setting a benchmark for the company’s global operations.

Since 2018, the WEF Global Lighthouse Network has recognised industrial sites achieving exceptional performance in productivity, supply chain resilience, customer centricity, sustainability and talent, highlighting the role of AI and digital innovation in modern manufacturing.

Stay Connected with Global Railway Review — Subscribe for Free!

Get exclusive access to the latest rail industry insights from Global Railway Review — all tailored to your interests.

✅ Expert-Led Webinars – Gain insights from global industry leaders

✅ Weekly News & Reports – Rail project updates, thought leadership, and exclusive interviews

✅ Partner Innovations – Discover cutting-edge rail technologies

✅ Print/Digital Magazine – Enjoy two in-depth issues per year, packed with expert content

Choose the updates that matter most to you. Sign up now to stay informed, inspired, and connected — all for free!

Thank you for being part of our community. Let’s keep shaping the future of rail together!

Related topics

Artificial Intelligence (AI), Digitalisation, Electric/Hybrid Rolling Stock, Infrastructure Developments, Operational Performance, Sustainability/Decarbonisation, Technology & Software, The Workforce