Dellner becomes the number one supplier for all types of railway couplers

Posted: 5 February 2020 | Dellner | No comments yet

Following the transfer of ownership of Dellner Couplers AB to Swedish Private Equity Company EQT AB, Dellner will look to the future with improved safety, quality, sustainability and customer focus.

In June 2019, the final signatures were given to transfer the ownership of Dellner Couplers AB from Gunnar Dellner and Clas Nicolin to the Swedish Investment Group EQT. With fresh capital and ideas, the successful road of the past is now paved for the future.

The Dellner coupler business for passenger trains has grown 20 per cent per annum historically and will remain the backbone for the coming years. New product and business developments were initiated to enhance the portfolio of passenger rail couplers, and at the same time the growing requirements for lower lifecycle cost and a more flexible supply chain has been given increased focus. Geographical regions have been defined to strengthen Dellner’s presence for the benefit of operators and to support local needs with increased availability and response.

The Dellner coupler business for passenger trains has grown 20 per cent per annum historically and will remain the backbone for the coming years.

The gangway business has grown strongly over the past years and that position will be continuously reinforced with an increased focus on successful designs for the mass market.

The full integration of Dellner Dampers opens new doors for Dellner’s market presence in the segment, while the development of the DAC freight coupler expands the future accessible market extraordinarily with freight car producers and freight operators.

History

Founded in 1941 in Falun, Sweden, Dellner Couplers AB is still today directing the global group from this remote spot in the middle of wonderful nature and one of the most important areas in Sweden for all-season recreational activities. Surrounded by abandoned lakes, forests and mountains the region hosts not only many international sport events during the winter and music festivals during the summertime, but attracts young and experienced talents to work in this environment for Dellner with an open window to the whole globe.

This set-up is a key contributing factor to Dellner being ranked in eighth place out of 728 Swedish companies in 2018 judged on successful growth. But it is surely not the only factor. Dellner has undergone a substantial change since the present CEO David Pagels took office in 2013. Reorganising Dellner’s structure, installing focused development and investment processes in regional offices in combination with the attraction of experienced specialists for management positions has collectively led to rapid growth. The turnover doubled within four years, the number of local subsidiaries grew to 22 offices in 16 countries whereby in India, Poland and in the USA brand-new factories where built up. Close to 1,100 people work for Dellner today.

In 2018, Gunnar Dellner decided to sell the company and the process started in October the same year. Several months of negotiations with numerous parties finally led the start of a new collaborative partnership together with EQT.

In 2018, Gunnar Dellner decided to sell the company and the process started in October the same year. Several months of negotiations with numerous parties finally led the start of a new collaborative partnership together with EQT.

EQT, the Sweden-based Investment Group, was founded in 1994. EQT’s legacy is closely linked to the Wallenberg family where entrepreneurship and an industrial growth approach have been the very core of the business model since inception. EQT employs over 700 people in 15 countries across Europe, North America and Asia Pacific, and is backed up by an investment history of more than 150 years.

During the second half of 2019 a Full Potential Plan was initiated at Dellner to refine and crystallise the strategy for the coming five years. The strategy entails a strong focus on accelerated sustainable growth driven by increased investments and efforts in innovation and product development, go-to-market processes, continued geographical expansion, and refined organisational set-up and motivation.

Safety, quality, sustainability and customer focus will be the driving elements in the journey towards Dellner’s future.

Dellner service

There is no kind of service missing in Dellner’s scope. On top of maintenance, spare parts, repairs, upgrades, and overhauls, the most unsurpassed feature is the response time.

Dellner has developed all service activities around the philosophy that 24 hours reaction time is not good enough, and that 24 weeks should be the maximum preparation time for a complex overhaul, even in the case of servicing non-Dellner couplers.

This was achieved by:

- Opening workshops in all important trading spots for our couplers

- Establishing a high-tech planning team in Poland for global operations

- Creating a mobile service container for all services directly at the operator’s site

- Monitoring fleets together with the operator, supporting processes and training staff.

The vision is to reach 100 per cent availability of the rolling stock concerning our products by using digital technologies. Remote diagnostics with Dellner ConneXion & Monitoring (DXM) are maximising the value of using couplers for our customers. On-time visibility of the state and condition of certain critical coupler functions allow preventive actions whenever needed.

Couplers

As complete as Dellner’s services allow the operator to have a single point of contact for all requirements, the coupler portfolio can cover all needs of advanced rolling stock producers.

Couplers for high-speed trains, metros, light-rail vehicles, mainline vehicles, people movers, locomotives, and freight cars, are available in thousands of different combinations, yet most cost effective in the market.

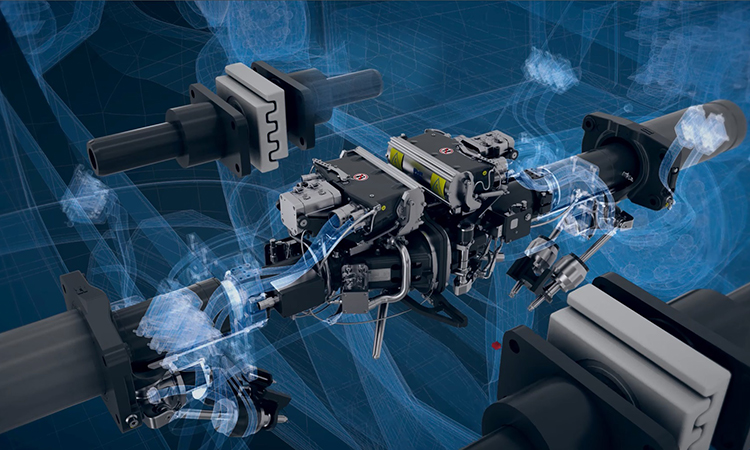

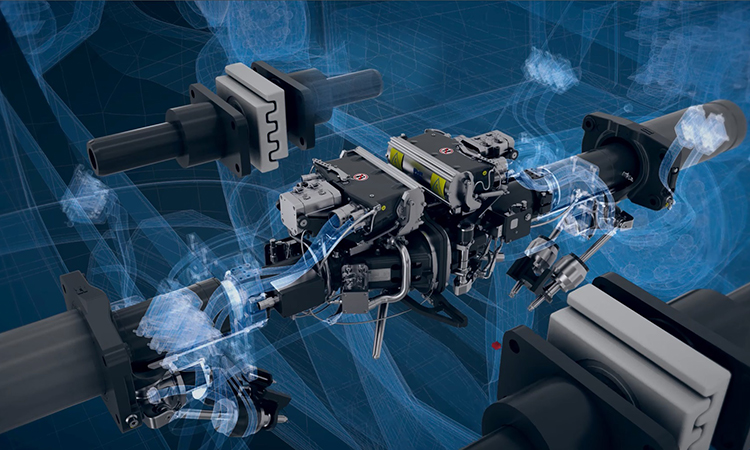

Couplers for high-speed trains, metros, light-rail vehicles, mainline vehicles, people movers, locomotives, and freight cars, are available in thousands of different combinations, yet most cost effective in the market. The reason is modular engineering: All coupler sections such as coupler head, coupler shank including the energy absorbing features, the electrical coupler and the pivot anchor with the interface to the car body, are based on modular engineering principles. This allows Dellner to source modules globally in larger quantities or to utilise own manufacturing facilities in China, India, Poland or USA to maximise internal resources.

Dellner is following its customers’ and national requirements by establishing localisation workshops in order to provide an efficient locals-with-locals model. The United States, China and India are of course given, but even in smaller yet critical areas like Malaysia, Argentina and Turkey or for important demand in Russia or Australia, Dellner is well prepared to respond in time of the project development.

Gangways

Even though a newcomer in the product segment Dellner was the first company to offer a 15-year service time in a market that was used to change gangways every eight years. Today, this becomes more and more the standard, but depending on the design even longer periods for gangway lifetimes are possible.

Top of line fire standards, extreme movements for airport people mover vehicles or monorails, inner panels, low noise applications, safety barriers or aesthetic designs can be adopted to all customer wishes.

With its newest gangway production in Chennai, India, Dellner combines local engineering creativity with available resources to serve European and Asian projects whereby the Indian market itself is one of the most interesting and fastest growing areas in Dellner’s gangway strategy.

Dellner Dampers

Since 2003, Dellner Dampers with its technology centre in Flen, Sweden, has been serving not only Dellner Couplers with gas hydraulic solutions for the energy absorption features, but also global OEMs with a range of energy absorbing and damping solutions. In parallel, an industrial segment has been developed with success in the material handling and bridge industries where special solutions are required.

The main focus remains on competitive solutions for the rail industry with coupler dampers, crash and side buffers, Inter-car- and Yaw-dampers as key product areas. Here the long evolved competence and quick response time are key to meet customer demands.

One of the most successful inventions was applied on metro couplers in 2014. The double-acting-Damper that replaced the ring spring for draft forces became in short time a unique feature for Dellner Couplers. The much-reduced building volume saved weight right from the beginning and maintenance efforts over the long-term. Since then, the design has been applied on other force levels similarly.

Benefitting from Dellner’s global network, all kinds of damping solutions can be serviced at a site that is optimal from a logistic and price perspective. For instance, dampers operating in North America could be serviced at one of Dellners U.S. sites, providing fast lead times for the customer. The vast majority of Dellner Dampers’ products can be overhauled to a more or less new status, which is beneficial both from a lifecycle cost and sustainability perspective. If the customer, by any reason, prefer to exchange the used damper with a new one, we offer solutions that are equivalent to the Dellner installed base, and competitive to third-party products, all according to latest standards.

Expansion into freight

After 10 years of planning and circulating convincing arguments, the critical mass was finally reached to re-start the attempt to replace all European freight couplers to automatic or semi-automatic ones. European rail institutions have requested proposals, and Dellner has responded and will be part of this exciting journey. During the present year Dellner will supply couplers to Trafikverket in Sweden and also to Austria’s railways for testing. If these tests are positive and the European associations approve the latch type couplers as the standard for the freight market, Dellner will be one of the largest suppliers for freight car builders and freight operators.

The vast amount of couplers that needs to be replaced in a very short timeframe over four to five years will require intelligent sourcing and improved logistical concepts. With the global supply chain Dellner is operating already today, this will become a key success factor for the project.

With the excellent customer relationships Dellner has enjoyed to build up based on quality and on-time deliveries over the past five years, with the motivation and creativity that recently has been reinforced together with our new owners, and with the foreseen market dynamics, Dellner is looking forward to a very bright future.

Related topics

Rolling Stock Components (Interior/Exterior), Rolling Stock Maintenance, Rolling Stock Orders/Developments, The Supply Chain