Implementation of environmental impacts within public procurement at ÖBB

Posted: 1 February 2021 | Matthias Landgraf, Sven Schirmer | No comments yet

On the path to climate neutrality, Austrian Federal Railways (ÖBB) have set a goal of integrating environmental impacts caused by products and services into its procurement process. Matthias Landgraf, Senior Scientist at TU Graz, and Sven Schirmer, ÖBB’s Corporate Procurement Coordinator for Rolling Stock, explain more.

The model we present in this article, which was developed in cooperation between the Austrian Federal Railways (ÖBB) and Graz University of Technology (TU Graz), enables a product-specific calculation of the environmental impacts caused by the production, construction and use phase in the context of public procurement. These environmental impacts are monetised and integrated into the Total Costs of Ownership (TCO). This results in a direct inclusion in the tendering process. The consideration of climate-relevant advantages of low-emission products and services as a cost factor in the procurement process creates an opportunity to encourage innovations of companies regarding mitigation of environmental impacts.

ÖBB is made up of several companies and an overarching holding company. The Strategic Group Purchasing Department of the holding company controls, among other things, an annual investment of more than €2 billion for the railway infrastructure. These are divided into four categories:

- IT and communication

- Construction services and supplies

- Cross-sectional materials

- Technical goods and services.

In the past, ÖBB has included follow up costs within the procurement process in accordance with legal requirements. It has been ÖBB’s practice for years to demand energy consumption, expected maintenance and spare parts costs or, for example, necessary renovation costs when submitting a bid. Since the acquisition of the Railjet high-speed train in 2005, the tenders regarding rolling stock have been handled completely according to the Total Cost of Ownership (TCO) approach.

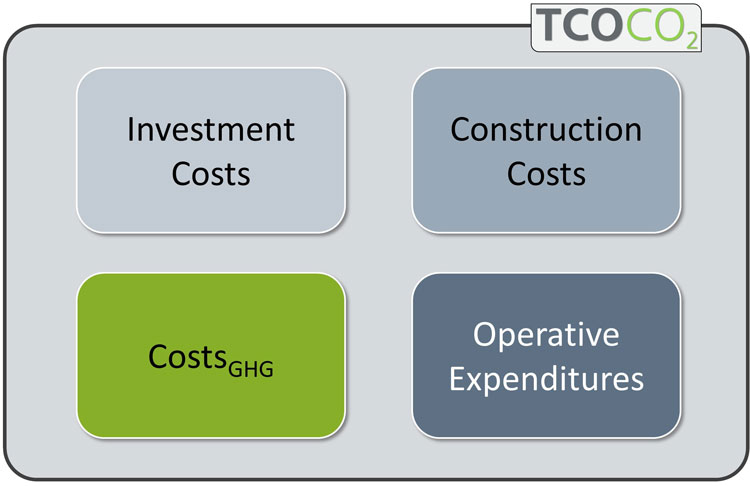

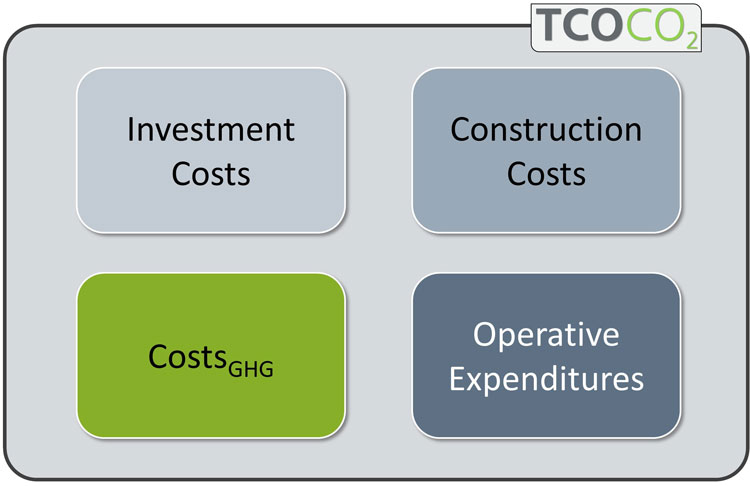

The aim of the TCO CO2 project is to develop a model that calculates the offer-specific environmental impacts in production, construction and operation. This allows a direct integration into the existing TCO methodology. As shown in Figure 1, the existing TCO methodology is to be extended to include the costs caused by environmental impacts (CostsGHG).

Figure 1: Structure and components of TCO CO2

Structure of the model

The basic requirement for the model to be integrated into the TCO methodology is an order- and bid-specific calculation of the environmental impacts. This means that, for each individual bid submitted by the bidder, the environmental impacts specific to this tender are to be determined.

The level of detail selected for this model requires input data that also do justice to this level of detail. For this reason, the calculation model of the environmental impacts in this first version refers to greenhouse gas (GHG) emissions in the form of CO2 equivalents (CO2e), according to the regulations defined in the Kyoto Protocol1, since these can already be determined with transparent, objective and comparable data.

In order to meet the necessary requirements of transparency in the context of public procurement, only published data and, thus, no licensed databases are to be used. Therefore, the Environmental Agencies of Austria2,3 and Germany4, as well as published Environmental Product Declarations (EPDs), are used. These EPDs are Type III environmental declarations according to ISO 14025 and EN 15804, which provide quantified environmental information from the lifecycle of a product or service to enable comparisons between products or services with the same function. They refer to individual products of companies, are certified by external experts and made available either on the respective company’s website or in corresponding databases5,6.

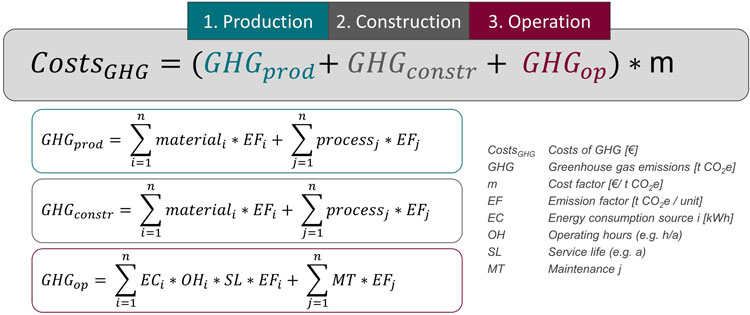

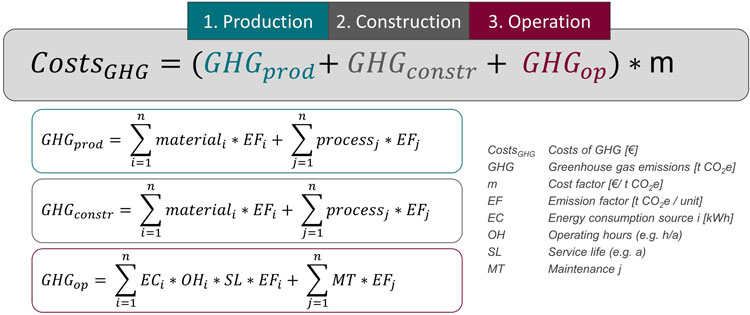

The share of environment-related costs (CostsGHG) is made up as shown in Figure 2. The GHG emissions of production and construction are dominated by the materials used and the necessary processes. The use phase is defined by the energy consumption of individual energy sources and necessary maintenance measures.

Figure 2: Calculation of costs associated to environmental impacts.

To have sufficient competing bidders available in a tender, a weighted model is used for an initial transitional period at ÖBB, in which offers are assigned CO2 points based on the calculated emissions. After this transition period, the monetarised environmental costs, as described in the context of this publication, will find direct input into the TCO.

An essential input variable in the sense of monetarising external costs and, thus, also in the model is the monetarisation factor. In the present model, a currently realistic monetisation factor of 20 €/t CO2 is applied on the recommendation of the Austrian Environment Agency. At the end of 2020, there were already initiatives to price greenhouse gas emissions in 64 countries, which together cover 22.3 per cent of global emissions7. Prices for emitting one tonne of CO2 equivalent vary widely around the world. The highest implemented CO2 tax rate is charged by Sweden, with the equivalent of 116 €/t CO2 (as of August 2020). These initiatives mainly serve to compensate for CO2 avoidance costs. The actual damage costs are currently estimated at up to 180 €/t CO28. Accordingly, sensitivity analyses with higher monetisation factors than the currently selected 20 €/t CO2 are also carried out within the scope of the application example.

Application

The methodology presented will now be illustrated using an application example. This directly shows the extent of the steering effect achieved in the context of procurement. Rail and rail vehicles are chosen as application examples.

An EPD9 prepared and published by voestalpine AG serves as input data for the calculation of GHG emissions in the context of rail production. The modelling of the maintenance activities themselves could be carried out based on internal records of ÖBB Infrastruktur AG.

The detailed calculation of GHG emissions of relevant maintenance activities (rail surface treatment and rail replacement) includes fuel consumption of transport distances from/to construction sites and maintenance work itself based on Austrian conditions and analysed shift lengths. Moreover, environmental impacts associated to the production of materials used for maintenance activities are considered.

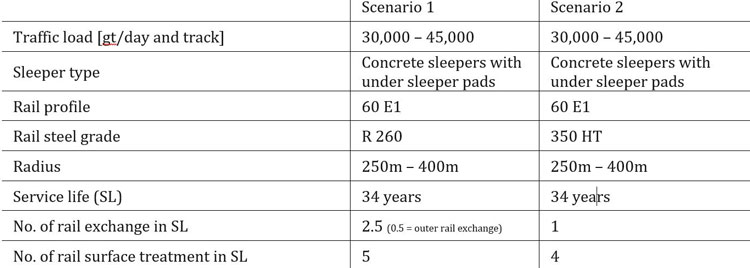

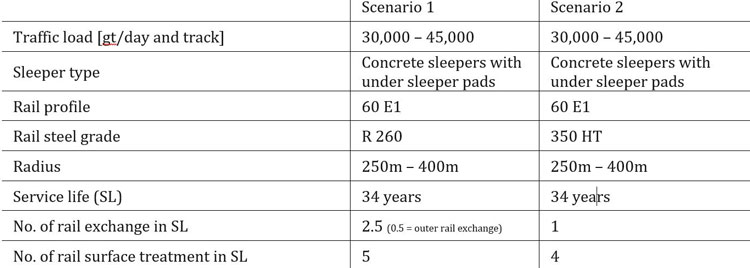

The relevant comparable parameter for strategic decisions is the emissions from production, construction and use phase in annual terms. Therefore, the service life of the product is of particular importance in addition to the number of maintenance measures. This information can be drawn from the so-called standard elements10 of ÖBB Infrastruktur AG, which depict the expected working cycle including maintenance measures and service life under specific boundary conditions. Table 1 shows a comparison for the use of rails in a curved track section with different rail steel grades and specific boundary conditions within the Austrian network.

Table 1: Comparison for the use of rails in a curved track section with different rail steel grades and specific boundary conditions within the Austrian network.

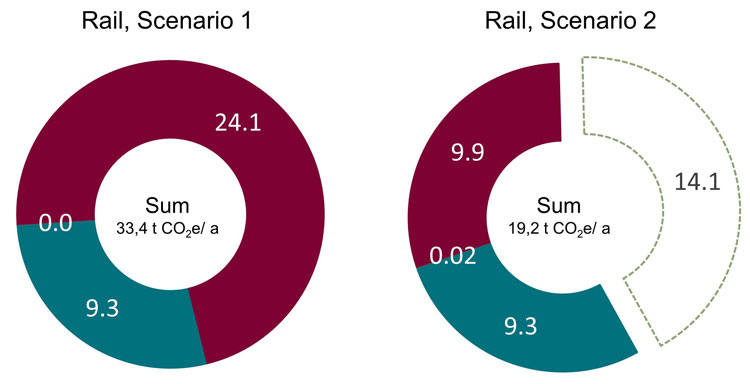

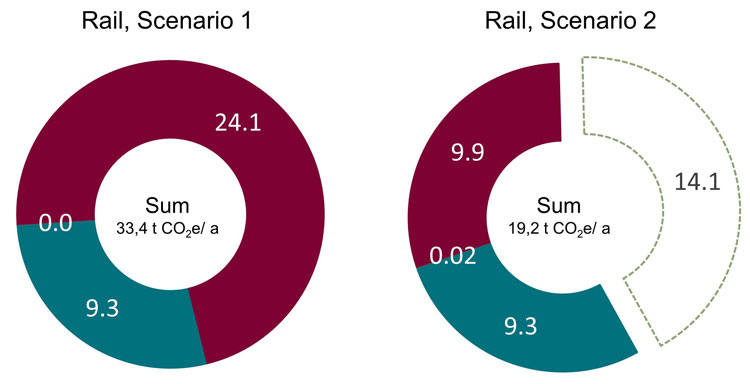

The use of the rail steel grades R 260 and 350 HT has no influence on the service life of the track under these specified boundary conditions, but it does have an influence on the necessary maintenance measures. For this reason, the GHG emissions (CO2e) caused for scenario 1 and scenario 2 differ to 33.4 tonnes CO2e and 19.2 tonnes CO2e per year, respectively (Figure 3). The share between production and use phase also shows a different behaviour, as scenario 1 requires a higher need for maintenance measures. This has a particular effect on the measure of rail replacement, including the activity itself, as well as the necessary material. The construction (installation of the rail) at the beginning of the service life takes only 0.02 tonnes of CO2e per year for both scenarios. In the context of scenario 2, the mitigation potential of greenhouse gas emissions compared to scenario 1 of 14.1 tonnes of CO2e per year is also shown.

Figure 3: Greenhouse gas (GHG) emissions of rails for different scenarios.

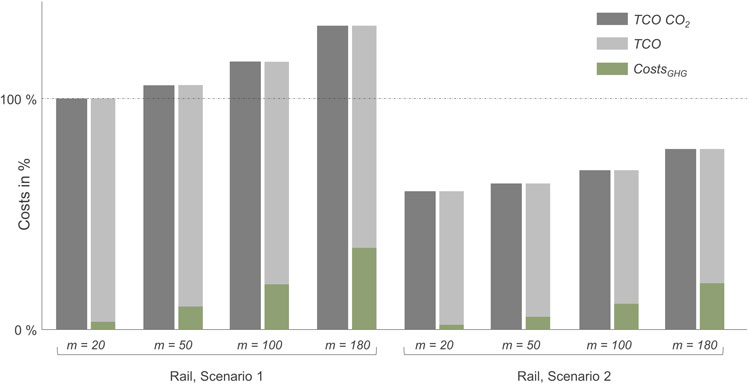

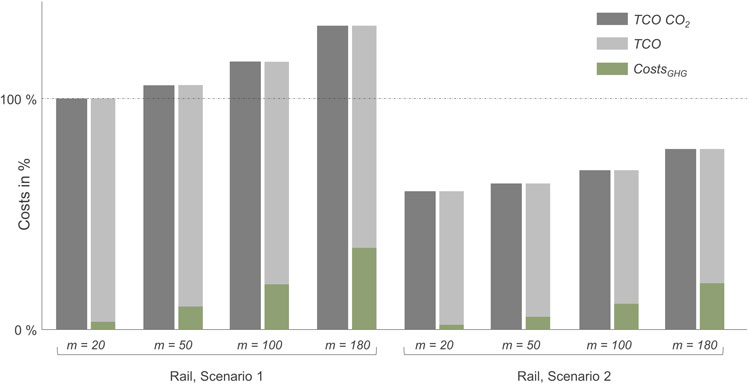

Consequently, the monetary effects can also be calculated within the framework of the TCO. Figure 4 compares the total TCO CO2, as well as the respective shares of TCO and CostsGHG, for the respective variants and different monetisation factors. Even with the current monetisation factor of 20 €/tonne CO2, the costs of GHG emissions already take up about four per cent of the total TCO CO2. Depending on the level of the monetisation factor, this steering effect increases up to 27 per cent.

Figure 4: Proportion of costs associated to environmental impacts (CostsGHG).

Outlook

The previous model of ÖBB, based on the total cost of ownership approach, is expanded to include the costs of the GHG emissions caused. The greenhouse gas emissions of production, construction and use phase of products and services are monetised and are, thus, directly included in the procurement process as part of the so-called TCO CO2.

After successful internal approval, the TCO CO2 tool is used in all new procurement projects. Currently, this is still in the form of a point-based system referring to the calculation of emissions presented. In the medium term, the direct integration of emissions by means of a monetisation factor is to be implemented. Part of the project was also the establishment of a training programme, not only for employees of the Austrian Federal Railways, but also for bidders. By actively raising awareness among existing and potential bidding companies, a broad acceptance of the necessary procedure can be achieved.

A survey within the industry and associations initiated by the project team also showed that there is a fundamental willingness to pay CO2 levies or to include environmental costs in the awarding of public contracts. This has clearly shown Austrian Federal Railways that, by taking the presented TCO CO2 into account, they are on the right track to meet the government’s requirements and, thus, lay the foundation for the mitigation of environmental impacts by including CO2 emissions within their procurement process.

References:

- United Nations Framework Convention on Climate Change, Kyoto Protocol on accounting of emissions and assigned amount, 2008

- Umweltbundesamt Österreich; umweltbundesamt.at/studien-reports

- Umweltbundesamt Österreich; GEMIS Globales Emissions-Modell integrierter Systeme – Österreich, Version 4.9

- Umweltbundesamt Deutschland, ProBas: Prozessorientierte Basisdaten für Umweltmanagementsysteme, probas.umweltbundesamt.de

- Deutsches Bundesministerium des Innern, für Bau und Heimat; oekobaudat.de

- EPD International AB, The international EPD System, environdec.com

- Carbon Pricing Dashboard, Worldbank, carbonpricingdahboard.worldbank.org, aufgerufen 23.11.2020

- Matthey A., Bünger B. Methodenkonvention 3.0 zur Ermittlung von Umweltkosten, Deutsches Umweltbundesamt Dessau-Roßlau, 02/2019, ISSN 1862-4804

- EPD-VOE-20190094-IAC1-DE, voestalpinge AG, 2019

- Marschnig, S. et. al.; Fahrwegstrategien für Gleis und Weiche auf Komponentenbasis – Optimierung auf Basis von Lebenszykluskosten, ZEVrail Glasers Annalen 130 (2006), 11-12, S. 500 – 508

Related topics

Related organisations

Graz University of Technology, ÖBB-Holding AG, ÖBB-Infrastruktur AG