The new Lyon-Turin railway line: Eliminating the alpine bottleneck

Posted: 9 August 2021 | Mario Virano | No comments yet

Mario Virano, TELT-Tunnel Euralpin Lyon Turin General Director, celebrates the project’s milestone as 80 per cent of the contracts are awarded, reflecting on the time and expertise needed to reach this point, while looking ahead to the end goal – the central rail link in the Mediterranean Corridor.

The project and how we got there

For the new Lyon-Turin railway line, 2021 marks a turning point, with the award of the contracts for the entire cross-border base tunnel. This is an important milestone for the project, and it comes after the completion of a complex approval process in Italy and France (concluded in 2017) and, even before that, the termination of the fundamental feasibility and study phases.

Today, TELT – the French-Italian public promoter of the project – is working on the realisation of a project that has a European vocation and the ambition to be part of the Green Deal, for at least two reasons: the contribution that the railway offers to decarbonisation, and the lower energy consumption that the base tunnel requires for transport, compared to the existing mountain line. Not to mention the significant reduction in time and costs for freight and passenger transport across the Alps.

The cross-border section of the Lyon-Turin line is the central link in the Mediterranean Corridor (on the European east-west axis), one of the nine axes of the TEN-T transport network. The new infrastructure provides a link south of the Alps between Western and Central Europe; it aims to promote economic exchanges and strengthen the competitiveness of the Mediterranean European countries and is based on a freight/passenger rail network, which also passes near to major sea and river ports, large cities and airports.

The cross-border section connects the international stations of Saint-Jean-de-Maurienne (in Savoie, France) and Susa (in Piedmont, Italy), where the new railway connects to the existing line. It is 65km long, with 89 per cent of it passing through tunnels and most of the above-ground facilities located in already built-up areas. The key element is the Mont Cenis base tunnel (double tube with single track) through which the trains will travel. With its 57.5km of length (45km in France and 12.5km in Italy), it is the longest railway tunnel in the world.

One hundred and fifty years after the inauguration of the Fréjus railway tunnel (at an altitude of 1,300m), through which the current historic line passes, the construction of the new line is a solution that meets current transport standards and makes rail transport more competitive.

The result of the participatory process on the Italian territory marked not only a radical modification of the route, but also had the effect of changing the opposition, which today no longer sees all the administrators of the Susa Valley serried in the front line against the project.

Current progress

Today, 13 new companies that won the tenders for the base tunnel on the French territory are about to set up on the construction sites. They join more than 150 companies and professionals already working on the sites on the various aspects of the project, from engineering, excavation and environmental monitoring, to supplies.

The awarding of the contracts for 80 per cent of the tunnel, representing 100 per cent of the route on French territory, marks a major step forward which, together with the awarding of the remaining 20 per cent (the lot on Italian territory), will be the definitive turning point towards completion within the timeframe established with the European Union, which may also take into account the impact of the pandemic.

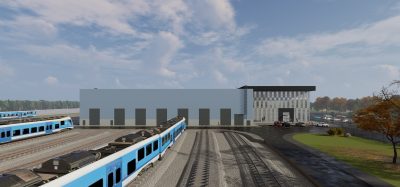

On the base tunnel, work is advancing and the 10km of the south tube through which trains will travel have been completed: 9km have been excavated using the Federica tunnel boring machine, while work is proceeding with traditional methods at Saint-Martin-la-Porte. In parallel with the advance of the base tunnel, work is being carried out above ground on French and Italian territory.

On the cross-border section, the work just assigned will start from the access points already completed: the four access adits provide access points for work vehicles and, at full capacity, there will be 15 excavation fronts and seven tunnel boring machines advancing simultaneously to complete the tunnel through which the trains will travel.

Next steps and future prospects (benefits and advantages)

In the next few months, we will be commissioning the excavation works on Italian territory, which will result in the award of 100 per cent of the route. Then we will have about 10 years of work ahead of us, comprising civil engineering works, equipping the tunnel and pre-operational work, before operation.

The construction of the Lyon-Turin line is part of the development of the European networks, and when the line will be fully operational, it is estimated that more than one million lorries will no longer travel across the Alps, reducing CO2 emissions by three million tonnes per year. The benefits that the project will bring also concern the creation of a greater freight interchange between Italy and France, but also an increase in the number of passenger trains, shorter travel times (e.g. Paris-Milan in four and a half hours instead of about seven hours) and a series of possible origins and destinations on different European routes.

There are various estimates of the economic impacts of the Lyon-Turin line during construction and when fully operational. It has been calculated, for example, that cross-border projects bring the greatest benefit to the European economy, with a multiplier three times greater than the average for the nine TEN-T corridors.

Finally, the real major multiplying benefit of the new infrastructure is the elimination of the Alpine bottleneck, which penalises not only the Lyon-Turin section (for 300km) but the entire Mediterranean Corridor of 3,000km and, pro rata, the 30,000km of the entire European network. It is on this scale, including from the energy point of view, that the base tunnel will have its full effect.

Stay Connected with Global Railway Review — Subscribe for Free!

Get exclusive access to the latest rail industry insights from Global Railway Review — all tailored to your interests.

✅ Expert-Led Webinars – Gain insights from global industry leaders

✅ Weekly News & Reports – Rail project updates, thought leadership, and exclusive interviews

✅ Partner Innovations – Discover cutting-edge rail technologies

✅ Print/Digital Magazine – Enjoy two in-depth issues per year, packed with expert content

Choose the updates that matter most to you. Sign up now to stay informed, inspired, and connected — all for free!

Thank you for being part of our community. Let’s keep shaping the future of rail together!