Interview Spotlight: CEO Dr Georg Friberg talks about how Goldschmidt has set up to support rail operators with smart inspection solutions

Posted: 12 May 2025 | Elizabeth Jordan - Global Railway Review | No comments yet

Global Railway Review speaks to Dr. Georg Friberg, CEO of Goldschmidt Group, a company that is known for having invented the Thermit® welding process for rails 130 years ago and that is the global market leader in this field of expertise.

In the past 15 years, Goldschmidt has engaged in a completely different area that has become a crucial topic for many track operators – the inspection of tracks.

What are the challenges for rail infrastructure operators today?

There are many challenges but there is one that we at Goldschmidt focused on when we started our engagement into what we call Inspection Solutions: the reliable maintenance of railway tracks.

We are active all around the world and talking to our customers we found that many of them face the same problem – a limited, sometimes even decreasing, workforce to maintain their networks. In order to secure the reliability and safety of their infrastructure they need to find new ways.

The first and most important information they need is an exact idea of the actual condition of the infrastructure and this is where we come into play. Based on this information maintenance activities can be defined and prioritized.

Road-Rail Inspection vehicle developed together with Kölner Verkehrs-Betriebe AG

What does Goldschmidt offer?

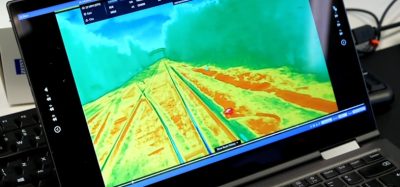

Goldschmidt has probably the most comprehensive product portfolio related to track inspection. We offer systems for laser-based geometry measurement of rails, tracks, switches but also wheels. In addition, we offer visual inspection systems examining ballast, clips, catenary, track clearance or signs. Finally, we offer special systems based on ultrasonic and eddy current sensor technology to detect flaws in rails or at the rail surface e.g. squats or head checks. All these systems consist on the one hand of the specific sensor technologies and on the other hand of the related software for analysing the data.

It is this data, describing the condition of the track, that can be used to define the necessary maintenance activities.

View the video here.

How do customers work with these inspection systems?

Customers have different approaches to use our systems. Large mainline infrastructure operators like Deutsche Bahn have integrated our eddy current and ultrasonic systems on their inspection trains for more than a decade and they operate the systems and analyse the data with some software support from us. In Italy, where we are about to deliver the same systems for the new fleet of inspection trains, the local infrastructure operator has ordered complete trains that they want to operate. Here we also deliver some special AI software for the data analysis. There are some large light rail infrastructure operators (metro and tram) who have ordered comprehensive integrated systems from us that we deliver either on a rail-bound trailer or on a road-rail vehicle. These vehicles are manufactured in our Swedish group company – one we had on display at the last InnoTrans. Finally, there are some customers asking us to operate the systems ourselves and supply the data, or – even one step further – just to give recommendations on maintenance measures. At the moment the market is developing quite fast and we are open to discuss these very different approaches.

What are Goldschmidt’s long-term goals in the railroad industry?

As a long-standing partner of the railroad industry and a family-owned company, Goldschmidt always followed a strategy that is based on long-term reliability – both in terms of the performance of our products and supporting our customers by solving their challenges. As we have done for more than a hundred years with the Thermit® welding process, we are now here to deliver and develop products and systems in the field of Inspection Solutions that help railway infrastructure operators to manage and improve their track maintenance. As of today, Goldschmidt has the most comprehensive product portfolio, operational experience and references in this field of activity.

About the Author

Dr.-Ing. Georg Friberg has been CEO of Goldschmidt Holding GmbH, the finance and management holding company of the globally active Goldschmidt Group, since February 2020. He has extensive experience in international corporate structures and family-owned medium-sized companies. Before joining Goldschmidt, the graduate physicist and electrical engineer spent more than ten years on the Executive Board and, from August 2009, as CEO of LISEGA SE, a leading global specialist in industrial pipe support systems based in Zeven (Lower Saxony). Prior to that, he held various positions at the energy and automation technology group ABB.

Related topics

Artificial Intelligence (AI), Big Data, Infrastructure Developments, Noise & Vibrations, Operational Performance, Refurbishment, Rolling Stock Components (Interior/Exterior), Rolling Stock Maintenance, Safety, Track Maintenance Machinery, Track/Infrastructure Maintenance & Engineering, Training & Development