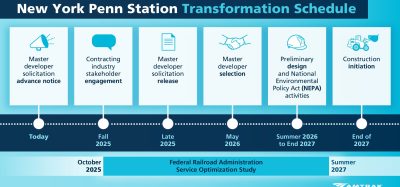

From manual checks to smart operations: The MONITOR project for freight rail

Posted: 6 November 2025 | Antoine Belleguie | No comments yet

Antoine Belleguie, Innovation Project Manager, Strategy & Development Direction, Rail Logistics Europe (SNCF Group) shares the potential of digital monitoring in optimising train operations through real-time data – if rail freight can move beyond historic operational practices.

As Europe seeks to shift freight from road to rail, improving the safety, reliability, and efficiency of rail freight operations has become a strategic priority. Yet, many essential procedures remain manual and labour-intensive, limiting both scalability and performance. The brake test — mandatory before every train departure — is perhaps the most emblematic example. Today, it still involves manually checking the braking response of each wagon, often under time pressure and in physically demanding conditions. To address this challenge, Rail Logistics Europe (SNCF Group), Wabtec, and Régie des Transports Métropolitains launched the MONITOR project in 2023.

The MONITOR project stems from a shared conviction: the future of rail freight depends on its digital transformation.”

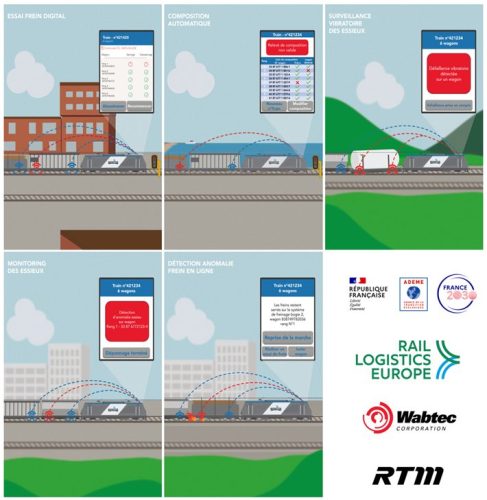

Funded by the French State as part of the France 2030 programme operated by ADEME, MONITOR is a digital monitoring system designed to optimise train operations through real-time data. The project stems from a shared conviction: the future of rail freight depends on its digital transformation.

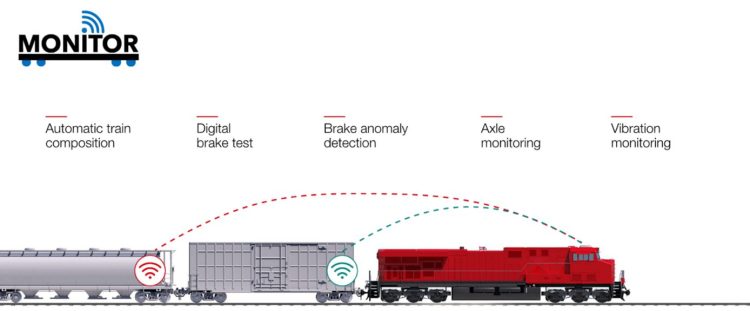

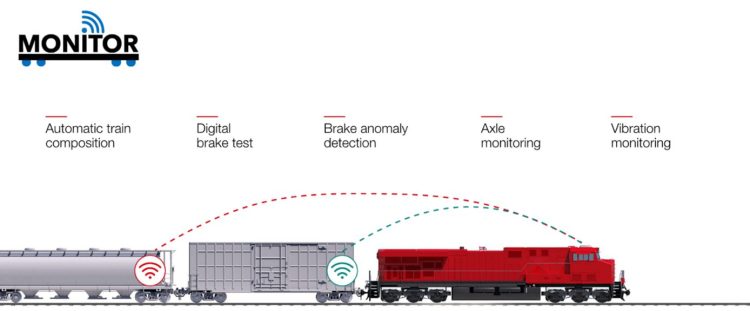

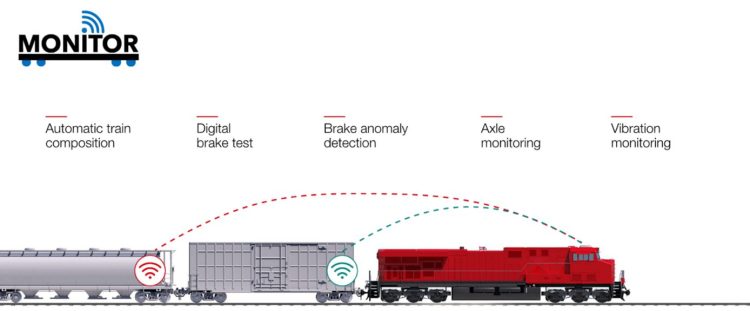

MONITOR will equip freight wagons with onboard sensors connected via wired links to control units on each wagon. The main control unit then communicates wirelessly with the central LCU — the brain of the system — which in turn interfaces with the driver through the HMI. This technology will enable the automation of brake tests and provide continuous monitoring of brake systems, vibration patterns, and the detection of locked axles or drag brakes — moving from static, manual checks to dynamic, real-time diagnostics.

Join our free webinar: Rail cyber-security in a time of technological and regulatory transformation

Join our expert panel, including speakers from Nokia and Siemens Mobility, to explore the critical convergence of cybersecurity and 5G rail comms.

Date: 3 Dec | Time: 15:00 GMT

Can’t attend live? No worries – register to receive the recording post-event.

The 2023 Gotthard Base Tunnel accident, which closed the west tube for almost a year, starkly illustrated the limitations of traditional visual inspections. The Swiss Safety Investigation Service (SESE) identified a wheel body rupture as the immediate cause of the derailment, leading the Federal Office of Transport (FOT) to tighten wagon maintenance requirements and impose enhanced inspections. More broadly, the incident reinforced an industry-wide recognition that future safety must rely less on manual checks and more on embedded diagnostics and continuous monitoring.

Context

Rail freight operators across Europe face three constant pressures: to remain competitive in a market dominated by road transport, to respond to growing climate imperatives, and to uphold the highest safety standards. Meeting these challenges requires innovation, yet many operational practices remain rooted in the past.

Rail freight must not only offer a lower-carbon alternative to trucks but also raise its service quality to attract new volumes.”

In some depots, it is still common for drivers to check brake tightening by simply kicking the wheels — a rudimentary practice that highlights how slowly the sector has embraced digitalisation. These manual methods, while historically simple and reliable enough to justify their persistence, are increasingly time-consuming, and they remain limited compared with what digital solutions can now provide in terms of accuracy and efficiency. They create inefficiencies that undermine punctuality, productivity, and ultimately competitiveness against road haulage. Surprisingly, such procedures have remained virtually unchanged since the early 20th century — making their digital transformation long overdue.

At the same time, the industry is under growing pressure to decarbonise and deliver on the EU Green Deal’s modal shift objectives. Rail freight must not only offer a lower-carbon alternative to trucks but also raise its service quality to attract new volumes. Digitalisation is emerging as a decisive lever in this transformation, enabling operators to combine higher safety, improved efficiency, and reduced environmental impact.

The MONITOR project is directly aligned with this ambition. By automating pre-departure procedures and introducing continuous monitoring of brakes and axles, it responds to operators’ growing demand for systems that are both reliable and responsive. The stakes are high: in France alone, 574 incidents related to locked brakes were reported in 2022 across all operators (SNCF Fret Safety Directorate, 2022), each representing a safety risk, a source of delay, and a cost to the system.

Technical description of MONITOR

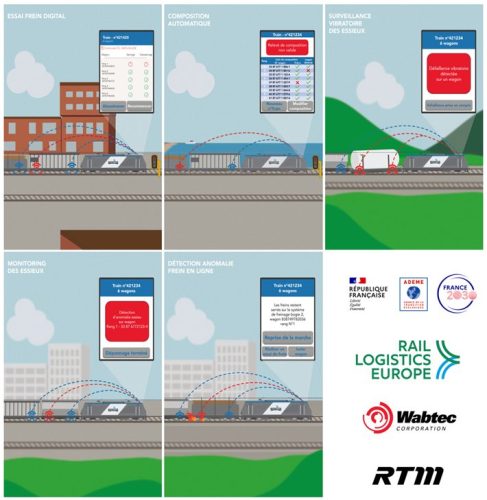

The MONITOR project has a clear ambition: to design, develop, and demonstrate a digital solution that will enhance both service quality and operational safety in rail freight. To achieve this, the project will be structured around five operational use cases — the digital brake test, in-transit brake anomaly detection, wagon vibration monitoring, axle monitoring, and automatic train composition verification — ensuring that each feature will address real-world operational needs.

Credit:Rail Logistics Europe (SNCF Group)

- Automatic train composition verification and digital braking bulletins: Today, braking bulletins are manually prepared by ground staff based on the declared train composition and wagon braking characteristics, before being handed over to the driver. While generally effective, this process is time-consuming and prone to human error. MONITOR will automate the task by combining declared data with sensor information and brake test results to generate and display an accurate digital braking bulletin. The result will be greater accuracy, improved safety, and more efficient operations.

- Digital brake test: A procedure that traditionally requires two operators will, with MONITOR, be carried out by the driver alone. By digitalising the process, MONITOR will significantly reduce physical workload and occupational risks for staff who would otherwise need to walk along long trains in demanding or hazardous conditions. Automation will also cut the duration of brake tests from up to 45–60 minutes for an 850 metre train to just a few minutes, enabling faster and more punctual departures. Results will be displayed in real time on the driver’s tablet, providing automatic confirmation of brake application and release, and eliminating the need for visual inspections.

- In-transit brake anomaly detection: Today, drivers have no real-time visibility of braking performance once the train is on the move. With MONITOR, brake behaviour will be continuously monitored, and any anomaly will immediately trigger an alert on the driver’s tablet. This will represent a step-change in dynamic safety for freight trains: by providing continuous visibility during the journey, it will help prevent incidents, including derailments in extreme cases.

- Axle monitoring: Issues such as locked axles or dragging brakes can remain unnoticed between scheduled inspections. MONITOR will continuously monitor axle behaviour and send immediate alerts to drivers and maintenance teams in case of such anomalies. This will enable faster, targeted interventions and accelerate the shift toward predictive maintenance, optimising costs while improving safety and reliability.

- Wagon vibration monitoring: This function will continuously monitor wagon vibration patterns. In case of irregularities, visual and audible alerts will be triggered on the driver’s tablet. As most European freight wagons currently lack such sensors, this monitoring capability will represent a significant step forward in improving operational awareness and enabling faster response to potential issues.

Credit: Rail Logistics Europe (SNCF Group)

Benefits of MONITOR

The MONITOR project is not only an innovation in digital technology; it is a strategic lever for making European rail freight safer, more competitive and more sustainable. By automating manual procedures, introducing continuous diagnostics, and enabling earlier anomaly detection, MONITOR delivers a broad spectrum of operational, economic, environmental and social benefits while paving the way towards predictive maintenance.

Operational impact

Pre-departure procedures are among the most time-consuming tasks in rail freight. Brake tests and train composition checks require several staff and immobilise locomotives for extended periods. With MONITOR, these operations will be automated and digitised:

- Time savings: By digitalising the brake test, MONITOR reduces a procedure that can take up to an hour on long trains to just a few minutes. This accelerates train readiness, limits locomotive idling, increases fleet availability, and improves overall network fluidity.

- Enhanced safety: Digital brake tests provide a more reliable validation of braking performance before departure, ensuring that anomalies such as locked brakes are detected immediately. This strengthens operational safety and reduces the likelihood of in-service failures, fires, or infrastructure damage.

- Extended asset life: By monitoring vibration and axle condition continuously, MONITOR detects anomalies at their earliest stage, allowing targeted interventions before damage escalates. Wheels, brake systems and bogies last longer, which improves reliability while reducing costs.

Taken together, these improvements mean more punctual services, fewer unexpected immobilisations, and higher levels of safety and reliability across the network.

Credit: Rail Logistics Europe (SNCF Group)

Economic impact

The operational improvements delivered by MONITOR translate directly into economic value for all rail freight stakeholders:

- Lower maintenance costs: continuous monitoring reduces the need for expensive wheel reprofiling, premature component replacement, or corrective interventions after failures. Brake shoes, axles, and other critical parts last longer, reducing life-cycle costs.

- Reduced infrastructure damage: By helping to detect brake-related anomalies earlier, MONITOR lowers the likelihood of incidents such as track fires or derailments, thereby avoiding costly consequences like catenary damage, track blockages, or platform disruptions.

- Fewer incident recovery costs: Emergency operations — recovery trains, fire brigades, transshipment to trucks, lost cargo retrieval, or workshop repairs — represent a heavy financial burden. MONITOR minimises the frequency of such events.

- Optimised network performance: Incidents on main lines often trigger cascading delays and cancellations affecting passenger and freight traffic alike. By reducing the number of these events, MONITOR increases overall network capacity and resilience.

From an economic perspective, MONITOR will strengthen the competitiveness of rail freight by reducing external costs — costs that today weigh heavily in comparison with road transport. By avoiding disruptions, material damage, and safety incidents, it will make rail a more reliable partner for shippers. Just as importantly, by significantly shortening pre-departure procedures and reducing unexpected immobilisations, MONITOR will generate substantial time savings — a decisive factor for both operational efficiency and commercial attractiveness.

Environmental impact

Rail is already one of the most environmentally friendly modes of transport, but MONITOR amplifies these benefits by optimising operations and avoiding incidents:

- Lower greenhouse gas emissions: Shorter pre-departure times mean locomotives consume less energy while idling.

- Reduced air pollution: More efficient operations and fewer emergency interventions lead to lower emissions of particulates and other pollutants.

- Resource efficiency: By extending the service life of wagons, axles, and braking systems, MONITOR will reduce the consumption of raw materials and limit the environmental footprint of manufacturing and recycling processes. Longer rolling stock life means less demand for energy-intensive production of spare parts and components. In addition, by shortening pre-departure procedures and reducing unplanned immobilisations, MONITOR will improve train rotations and overall asset utilisation — maximising the efficiency of existing fleets and further lowering the sector’s environmental footprint.

In a context where transport is under pressure to cut its carbon footprint, MONITOR provides a concrete contribution to Europe’s Green Deal objectives.

Social impact

MONITOR also delivers a wide range of social benefits:

- Improved working conditions: Automation of manual brake inspections reduces the physical strain on ground staff, limits exposure to harsh weather and hazardous environments, and lowers the risk of workplace accidents.

- Greater job attractiveness: By shifting tasks from manual, repetitive checks to more technical, digital supervision, MONITOR contributes to modernising the image of railway jobs and the profession as a whole.

- Public safety: By reducing the probability of accidents, derailments, or fires, MONITOR strengthens trust in rail as a safe and reliable mode of transport. This has positive spill-over effects for passenger perception, logistics partners and public authorities.

Perhaps most importantly, MONITOR strengthens the systemic competitiveness of rail freight. Road transport has long benefited from faster turnaround times and higher flexibility. By cutting costs, saving time and improving safety, MONITOR narrows this gap and reinforces rail’s value proposition.

MONITOR test bench at Wabtec’s Piossasco site, visited by the consortium on 8 July 2025, as the project moves towards trials. Credit: Rail Logistics Europe (SNCF Group)

Next step

In 2026, the MONITOR technology will be tested on a limited number of wagons in real-world conditions. These pilot deployments will provide the opportunity to validate the system’s robustness and demonstrate its benefits in day-to-day operations.

Conclusion

At Rail Logistics Europe, we believe in the emergence of an intelligent freight ecosystem.

Across the rail industry, there is a growing consensus that safety can no longer rely solely on manual inspections but must be secured through embedded diagnostics and continuous, data-driven monitoring. Such a transformation cannot be achieved by a single player. Only by combining operational experience with industrial expertise will these solutions successfully reach the market.

In the coming years, the “smart wagon” will become the new standard. With MONITOR, we are introducing the first technological building block towards safer, smarter, and more competitive rail freight.

If you’re interested in the broader shift toward smarter, safer rail freight, don’t forget to read Global Railway Review’s Track Insight, Unlocking the Future of Freight, which offers valuable perspectives on the latest developments as well as expert insights into where the sector is heading.

Meet the author

Antoine Belleguie is Innovation Projects Manager at Rail Logistics Europe (SNCF Group), where he leads MONITOR, a France 2030 flagship project deploying digital diagnostics on freight wagons, and GreenPower, advancing energy efficiency, eco-driving, eco-parking, and low-carbon alternatives such as HVO. Formerly at Alstom, he contributed to Europe’s first bi-mode electric–hydrogen freight locomotive. He has conducted doctoral research on the energy transition of rail transport and lectures on hydrogen engineering at IFP School.

OUT NOW: The Definitive Guide to Rail’s Digital Future

The rail industry is undergoing a digital revolution, and you need to be ready. We have released our latest market report, “Track Insight: Digitalisation.”

This is not just another report; it’s your comprehensive guide to understanding and leveraging the profound technological shifts reshaping our industry. We move beyond the buzzwords to show you the tangible realities of AI, IoT, and advanced data analytics in rail.

Discover how to:

- Optimise operations and maintenance with real-time insights.

- Enhance passenger services through seamless, high-speed connectivity.

- Leverage technologies like LEO satellites to improve safety and efficiency.

Featuring expert analysis from leaders at Nomad Digital, Lucchini RS, Bentley Systems and more, this is a must-read for any rail professional.

Related topics

Bogies & Wheelsets, Cargo, Freight & Heavy-Haul, Digitalisation, Freight, Operational Performance, Rolling Stock Maintenance, Safety, Technology & Software, The Workforce

Related organisations

Rail Logistics Europe (RLE), Régie des Transports Métropolitains, Wabtec