Video: HS2 celebrates tunnels reaching halfway point under the Chilterns

Posted: 1 February 2023 | Elliot Robinson (Editorial Assistant - Global Railway Review) | No comments yet

HS2 have confirmed that two giant tunnelling machines have passed the halfway mark during the excavation of the 10-mile-long Chiltern tunnels.

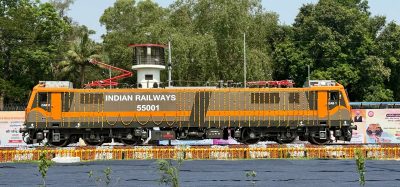

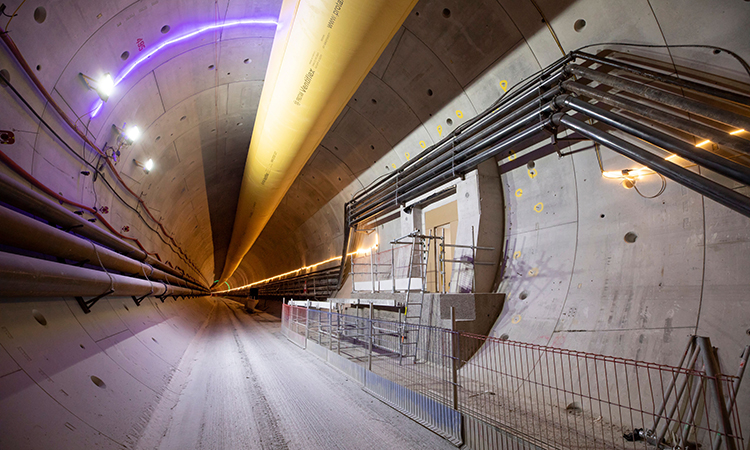

Partial walkway completed at the South Portal - Credit: HS2

HS2 Ltd has confirmed that ‘Florence’ and ‘Cecilia’, the two giant tunnelling machines excavating the high-speed rail project’s longest tunnels, have passed the halfway point on their 10-mile journey under the Chilterns. A video of this achievement can be found below.

The enormous 2,000 tonne machines have spent the last 18 months excavating the twin tunnels between the M25 and South Heath in Buckinghamshire that will help protect the environment while improving connections between London, Birmingham, and the North.

The tunnel excavation

As well as digging and lining the tunnels, engineers have also completed the excavation of five shafts that will provide ventilation and emergency access near Chalfont St Peter, Chalfont St Giles, Amersham, Little Missenden, and Chesham Road. They also recently completed the first breakthrough from a cross passageway to the shaft at Chalfont St Peter.

More than 1.3 million cubic metres of chalk and flint – enough to fill more than 500 Olympic swimming pools – has been excavated and will be used as part of an ambitious chalk grassland restoration project at the south portal of the tunnel. This will see the creation of 127 hectares of new landscaping, wildlife habitat and biodiverse chalk grassland.

Once complete, the Chiltern tunnels will carry high speed trains between London and the North at speeds of up to 200mph (320km/h), helping to improve connections, free up space for more freight and local trains on the existing railway and provide zero carbon journeys for people across the UK.

“It’s great to be able to celebrate the half-way point of this 10-mile-long tunnel,” Martyn Noak, Head of Tunnel Engineering for HS2, said. “The whole team has put in a fantastic effort over the last year-and-a-half and I’d like to congratulate the crews of both Florence and Cecilia for passing this important tunnelling milestone and thank them for all their hard work. This tunnel will take HS2 underneath the Chiltern hills, safeguarding the woodlands and wildlife habits above ground as well as significantly reducing disruption to communities during construction and operation. Once complete, HS2 will offer low carbon journey options linking London with the major cities of the north and releasing capacity for more freight and local trains on our existing mainlines.”

“Florence and Cecilia passing the half-way point on what is a long drive for the TBMs, is a great achievement,” Didier Jacques, Underground Construction Director for Align, said. “I would like to pay credit to TGT, our supply chain partner, whose personnel are manning the TBMs. This significant progress would not have been possible without the supporting teams on the surface at the South Portal, who supply the thousands of 8.5 tonne segments required to line the tunnels, process the spoil pumped back as slurry through our slurry treatment plant and landscape the chalk produced across the site.”

The Tunnel Boring Machines

The tunnel openings at South Portal, with both Cecilia and Florence TBMs inside – Credit: HS2

Designed specifically for the mix of chalk and flints under the Chilterns, the two identical TBMs are excavating separate tunnels for north and southbound trains. The excavated material is mixed with water to form a slurry, before being pumped back to the surface.

Each machine operates as a self-contained underground factory – digging the tunnel, lining it with concrete wall segments and grouting them into place at a speed of around 15 meters a day. More than 56,000 precision-engineered, fibre-reinforced segments have been installed to create the walls of the tunnels – with each one made on site in a dedicated temporary pre-cast factory.

A crew of 17 people operate each TBM, working in shifts to keep the machines running 24/7. They are supported by over 100 people on the surface, managing the logistics and maintaining the smooth progress of the tunnelling operation.

As well as the Chiltern tunnels, HS2 also recently launched two TBMs to begin the project’s London tunnels and celebrated the first breakthrough with the completion of the first of two tunnels under Long Itchington Wood in Warwickshire.

Related content you will enjoy:

HS2 finish foundation work for UK’s longest railway bridge

HS2 boosts Oxford-Cambridge connections with East West Rail bridge

Related topics

High Speed Two (HS2), Infrastructure Developments, Tunnelling