Superconducting Maglev: Speeding toward sustainability

Posted: 6 September 2022 | Wayne Rogers | No comments yet

In Global Railway Review Issue 4 2022, Wayne Rogers, Chairman and CEO of the Northeast Maglev, explains the importance of bringing high-speed travel to the United States through the SCMAGLEV train and explores the possibilities that this innovative technology offers passengers and the planet.

Central Japan Railway’s improved version of the Series L0 SCMAGLEV train.

The United States Northeast Corridor, which stretches from Washington, D.C. to Boston, Massachusetts, is notoriously overdue for a mass transportation improvement. With record levels of congestion, traffic, bottlenecks, and accidents compounded by projected population growth, it is evident that the issues are showing no sign of slowing down. We sorely need truly safe, efficient, reliable, and high-speed mass transit options. Overcoming an escalating rush hour is no longer the only challenge at-hand; the mounting impacts of climate change have highlighted the duty to tackle transportation needs without producing harmful greenhouse gas (GHG) emissions. Despite the odds, there is an ultra-low emission, reliable, and incredibly fast mode of mass transportation that is now up for the challenge.

The United States lags behind much of the world in true high-speed rail development. The SCMAGLEV system proves that we no longer must choose between the wellbeing of people and the wellbeing of the environment; we can choose both.

Northeast Maglev is working closely with Central Japan Railway (JRC) to bring the next generation of ultra-high-speed travel to the Northeast Corridor: the SCMAGLEV (Superconducting Magnetic Levitation) train. The innovative technology and impeccable safety standards inherent to the SCMAGLEV system will revolutionise high-speed rail development in the country, skipping an entire generation of technology and setting a sustainable standard for the nation’s transportation.

Mass transit is integral to reducing congestion and improving transportation reliability, as demonstrated by the effective high-speed rail rollouts in many EU and Asian countries. Yet, the U.S. remains without any true high-speed rail service, as defined internationally as over 300km/h (186mph). While the Chinese have built more than 10,000 miles of high-speed rail in the last decade, the U.S. has built none. The SCMAGLEV system will change this and offer travel between Washington, D.C., and New York City in just one hour at 500kph (311mph). The SCMAGLEV is much more than the typical high-speed rail system. Its new train models employ innovative technologies that set it apart from all other railways, and even its own maglev predecessors.

With revolutionary technologies and Northeast Maglev’s commitment to renewable energy sources, the SCMAGLEV foreshadows a desperately needed paradigm: expanded transportation ecosystems with a reduced reliance on fossil fuels and emissions. Building upon JRC’s continued dedication to increased efficiency, technological development, and speed, while maintaining the world’s best safety standards, the SCMAGLEV is a promise not only for a better future for our people, but for the planet as well.

The SCMAGLEV: Higher than high-speed rail

The SCMAGLEV is famous for its levitating train and extraordinarily high speeds. But it represents much more than just ultra-high-speed rail, as it relies on completely different, revolutionary technology. Conventional high-speed trains use friction between the wheels and rails to accelerate and decelerate. This limits the maximum speed because the wheels slip when moving too fast. Additionally, conventional high-speed rail depends on contact between overhead catenary wires and pantographs. At higher speeds, conventional high-speed rail operation increases contact wire vibration and causes frequent separation from pantographs, making stable power feed to the vehicles difficult.

The SCMAGLEV uses entirely modern mechanics, and the implications are massive. It’s propelled by the magnetic forces of a linear motor, meaning it can overcome the speed limits of conventional high-speed rail since there is no chance of higher speeds causing wheel slippage, nor does it require a catenary/pantograph system.

Travelling at 500kph (311mph) is only one of many feats that the SCMAGLEV achieves. As the SCMAGLEV levitates in a guideway, there is neither wheel-on-rail contact issues nor catenary/pantograph interactions. This means it is free from rolling and contact friction-induced noise. The magnetic interaction with the U-shaped guideway also eliminates the possibility of derailment, allowing the train to reach much higher speeds while remaining completely safe.

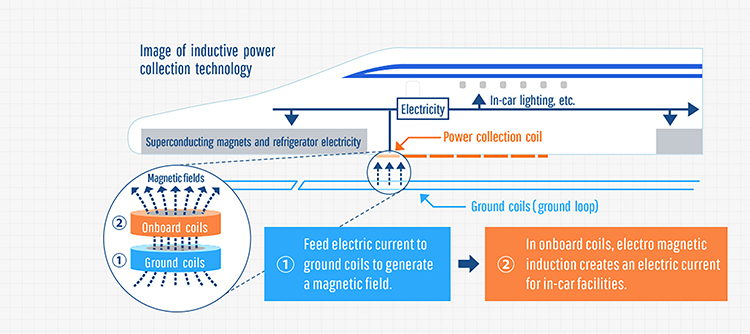

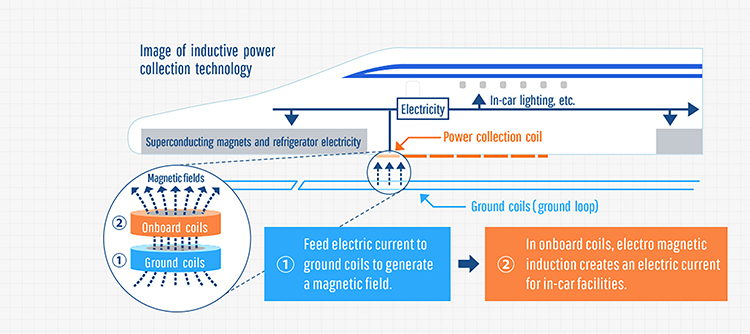

Moreover, by fully adopting a wireless induction power transfer method, JRC has facilitated stable contact and emissions-free electricity to the SCMAGLEV vehicle to power onboard electrical systems. The complete adoption of this wireless technology further sets the SCMAGLEV apart from all other rail systems, as it offers an even more sustainable mode of mass transit.

Superconductivity, coils, and currents

It is no secret that superconductivity is the force behind the Superconducting Maglev. The ability to harness the power of superconductive magnets opens the door to incredible possibilities and creative solutions in transportation, as well as other applications. Normal, non-superconducting electromagnets require a substantial amount of electric power to generate magnetic force, yet much of the energy is wasted as heat resulting from electrical resistance.

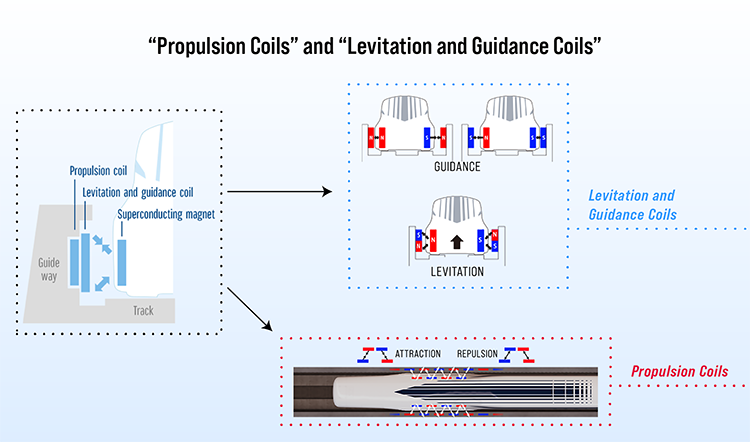

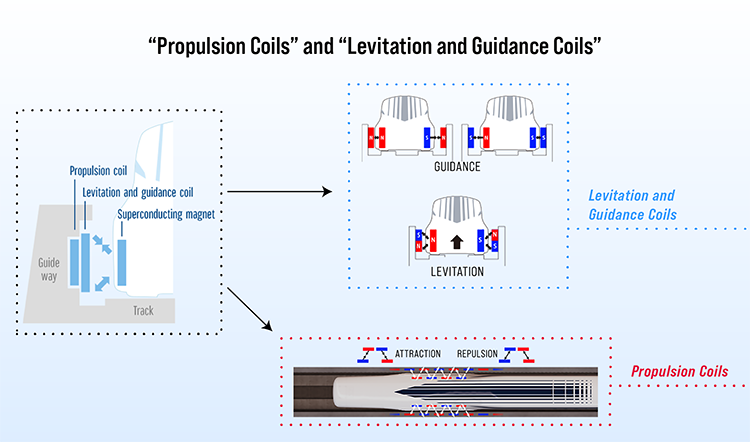

Superconducting magnets, on the other hand, take advantage of the effect of specific materials cooled to a very low temperature: electrical resistance starts to approach zero. When an electrical current is applied to a superconducting coil, the current continues to flow almost indefinitely. These superconducting magnets on the vehicle interact with two main sets of coils in the guideway walls. One set of coils levitate and guide the train; the other set of coils propel the train.

When superconducting magnets on the vehicle pass by the levitation and guidance coils at high speed, electric current flows through the coils and transforms them into electromagnets. These magnetic forces between the superconducting magnets and the coils in the guideway lift the train, levitating it above the guideway. Attractive and repulsive forces between these coils and the superconducting magnets on the train keep the vehicle centred in the guideway at all times.

Propulsion coils are responsible for acceleration and deceleration. The superconducting magnets on the vehicle are set to North (N) and South (S) poles alternately. The electric current is fed to propulsion coils on the guideway, and their N-pole and S-pole assignment is switched to propel the train forward. The frequency of electric current is adjusted to control the speed for switching between N and S poles to regulate the train’s speed. Superconductivity is key in unlocking this incredible method of propulsion (see Figure 1).

Figure 1

The Series L0 Improved Version: Inductive power breakthrough

In 2020, after years of thorough testing, JRC introduced the Series L0 Improved Version of SCMAGLEV trains, which Northeast Maglev also plans to adopt in the U.S. This series of trainsets has a new, more aerodynamic front shape, which reduces aerodynamic resistance of the front nose section by a whopping 13 per cent (see main image).

But perhaps one of the most significant changes between the previous and improved train is its complete implementation of a wireless induction power transfer system, or inductive power collection (IPC), to power onboard systems. In short, power is harnessed from the guideway as the train runs; this power is then used for onboard electricity, lights, air conditioning, and to power refrigeration of the superconducting magnets.

You may be more familiar with the concept of IPC than you think. In the same way that many modern smartphones can be charged by simply placing them on a charging pad, the SCMAGLEV system uses a comparable type of power transfer. The SCMAGLEV vehicle acquires electricity from the guideway to power onboard systems without making any physical contact. Electric current is fed to ground wires on the guideway to generate a magnetic field, and onboard coils draw electricity wirelessly from the ground wires to provide electric current for in-car facilities (see Figure 2).

The implementation of IPC in high-speed rail is ground-breaking, and it is the future of reducing maintenance and power reliability issues, as well as reliance on fossil fuels. IPC brings us one step closer to truly having a no emission high-speed rail option, which is undeniably good news for the planet.

Figure 2

The future of energy in infrastructure

The SCMAGLEV system proves that developing and deploying innovative technology to reduce our reliance on fossil fuels is possible. Northeast Maglev will source clean energy for electricity needs; this is not just an empty claim. As Chairman and CEO of Synergics Energy Services, my team and I have successfully engaged in over 60 successful renewable energy projects worldwide, including 45 per cent of the wind energy in Maryland. We are eager to further develop or contract renewable sources to offset the electricity requirements of the SCMAGLEV.

With rising climate concerns, we hope to see continued global investment in cleaner energies and more efficient transit options. Britain’s HS2’s inspiring Net Zero Carbon Plan and diesel-free construction sites further exemplify shifts toward prioritising the environmental impact. Meanwhile, some European countries, such as Germany, are introducing shockingly low public transit fares for public transit to incentivise its use over personal vehicles, with the ultimate goal of reducing fuel consumption. Investing in innovative technology, mass transit, and infrastructure is instrumental in serving both the needs of growing global populations, and the needs of our environment.

The first phase of the project, from Washington, D.C. to Baltimore, has already been deemed by the U.S. Department of Transportation’s Federal Railroad Administration via the Draft Environmental Impact Statement to result in an overall reduction in regional mobile source emissions, as the project predicts to divert up to 16 million trips annually from auto to SCMAGLEV. This is just the beginning.

The SCMAGLEV train is emblematic of technological potential that can be transformed into reality today. High speed, reliability, frequency, and safety do not have to come at the expense of the environment or wait for some future technology development. The United States lags behind much of the world in true high-speed rail development. The SCMAGLEV system proves that we no longer must choose between the wellbeing of people and the wellbeing of the environment; we can choose both. We can choose now.

Issue

Related topics

Electric/Hybrid Rolling Stock, High-Speed Rail, Infrastructure Developments, Operational Performance, Sustainability/Decarbonisation

Related organisations

Central Japan Railway (JRC), HS2 Ltd (High Speed Two), Northeast Maglev