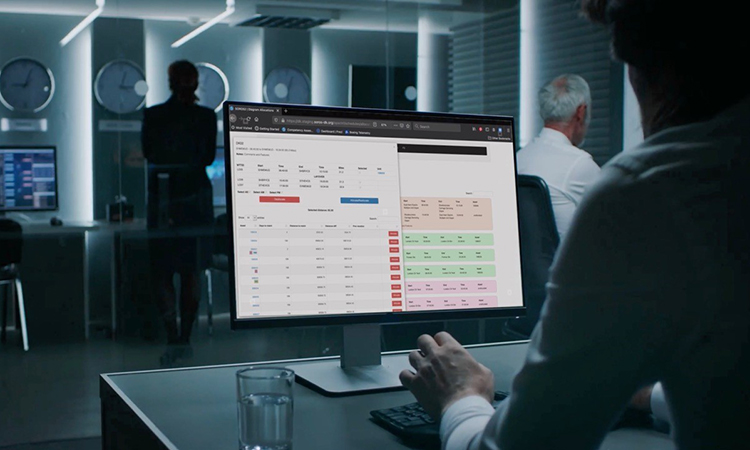

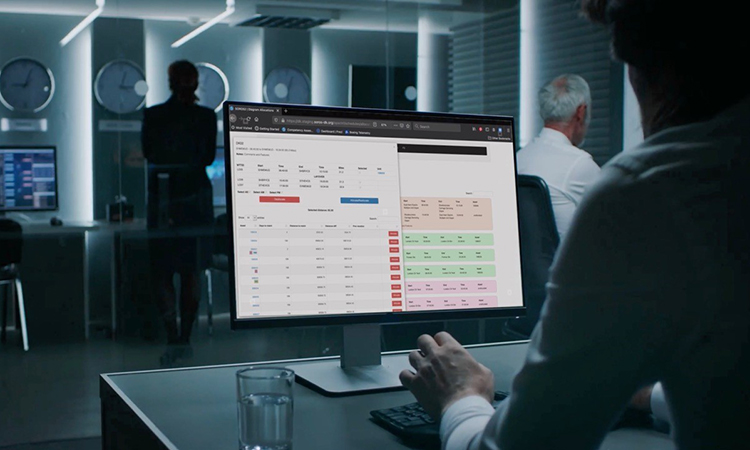

Northern roll-out transformative maintenance operations system

Posted: 5 June 2023 | Elliot Robinson (Editorial Assistant - Global Railway Review) | No comments yet

Northern are rolling out a game-changing operations management maintenance system that can tell the engineering team everything they need to know about their fleet of 345 trains.

Credit: Northern

Northern has begun the roll-out of a game-changing operations management maintenance system that experts are likening to a ‘concierge’ system for engineers.

The software, which is called SOROS, can tell Northern’s engineering team everything and anything they need to know about their fleet of 345 trains, including:

- Where and when each train will need its next ‘service’

- The maintenance history and upcoming safety checks required on every carriage

- The tools and parts required for each service to be carried out

- The skills and expertise to safely conduct that work

- The precise ‘parking space’ on the depot where the train needs to report to

- Where and when the train needs to be for its next passenger service

- It’s all part of a plan by Northern to revolutionise its entire engineering process by 2025.

Related content you will enjoy:

Customers to see new and improved information screens across Northern network

Northern appoint new Regional Director for Yorkshire, Humberside and East Midlands

“Our trains clock up an average of 500 miles a day as they ferry people across the North of England – and just like the car on your drive, those trains need regular servicing to keep them, quite literally, on track,” Jack Commandeur, Engineering Director at Northern, said. “SOROS allows us to plan that maintenance from start to finish, much further in advance – ensuring we have the right train in the right place at the right time in front of the right engineers. It’s all about optimising resources and ensuring trains remain in passenger service as much as possible. SOROS has ‘the knowledge’ to make that massive logistical challenge a whole lot easier.”

“SOROS helps organisations like Northern manage large-scale portfolios of complex assets through safety critical processes,” Rob Spence, Co-Founder of Danburykline, the creator of SOROS said. “The deployment of the system today is part of a phased roll-out across the business and is the culmination of a 16-month international tender process and it will transform their asset availability and reliability as well as reducing the cost of maintenance through efficiency of operation.”

Related topics

Infrastructure Developments, Regulation & Legislation, Track/Infrastructure Maintenance & Engineering