From the innovative freight wagon to the intelligent freight train

Posted: 16 September 2020 | Jürgen Hüllen, Stefan Hagenlocher | No comments yet

Colleagues from the Technical Innovation Circle for Rail Freight Transport (TIS), Project Manager, Stefan Hagenlocher, and Spokesman, Jürgen Hüllen, explain the objectives of the TIS towards strengthening the rail freight transport sector by supporting the growth and development of innovative freight wagons and intelligent freight trains.

The TIS brings together various stakeholders in the rail freight sector. As the sector’s practice group, the TIS has set itself the goal of initiating and implementing practical innovations for innovative freight wagons and intelligent freight trains. In doing so, it takes an integrated approach and focuses on the cost-effectiveness of innovations. Thus, participants in the TIS include wagon owners, railway companies and shippers, as well as companies from the wagon building industry and its suppliers. Currently, the following 14 companies are participating in the TIS: BASF SE; DB Cargo AG; DB Systemtechnik GmbH; ELH Waggonbau Niesky GmbH; Ermewa SA; GATX Rail Germany GmbH; Knorr-Bremse Systeme für Schienenfahrzeuge GmbH; Rail Cargo Austria AG; SBB Cargo AG; J.M. Voith SE&Co.KG; VTG AG; Wabtec Europe; Waggonbau Graaff GmbH; and Wascosa AG.

Innovative freight wagons

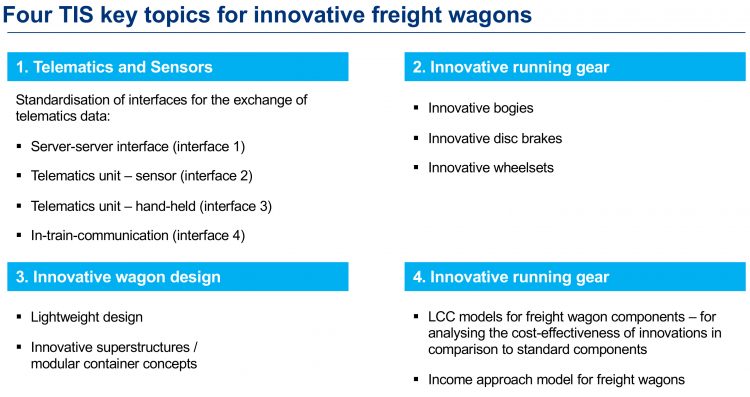

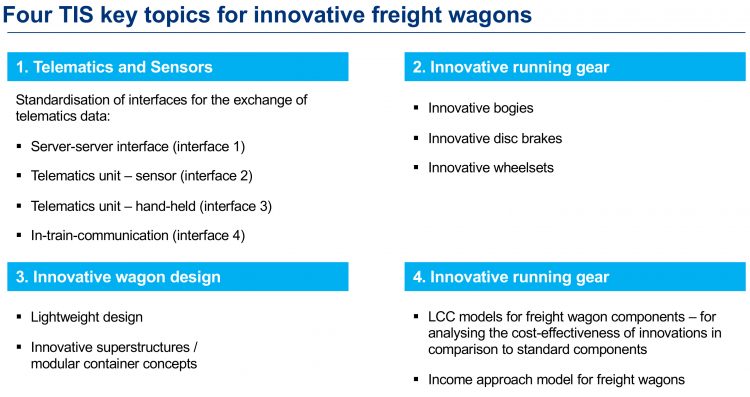

Low-noise, lightweight, long-running, logistics‑enabled, life-cycle-cost-oriented – the freight wagon of the future should meet all five of these basic criteria. In 2012, the whitepaper ‘Innovative Rail Freight Wagon 2030 – the ‘5L’ Future Initiative’, published by TIS, did more than formulate ambitious goals. It also presented the sector with a new approach for developing basic innovations using the concept of a demonstrator train. Basic innovations for freight wagons are telematics and sensors, innovative running gears and an innovative wagon design with a lightweight design, as well as a modular container concept.

The innovations described in Figure 1 will ensure that the freight wagons of the future are low-noise, lightweight, long-running and logistics-enabled. However, the fifth ‘L’ is of central importance: Life-cycle-cost-oriented. Innovations will only be adopted by the market if they are economically viable. To evaluate the cost-effectiveness and other effects of these innovations, various parties in the TIS have launched demonstrator projects, such as the ‘5L’-demonstrator of SBB Cargo and the ‘Innovative Freight Wagon’ by DB Cargo and VTG, as well as the innovative tank container concept of BASF. The results of the demonstrator projects are a positive signal for the future – as is the welcoming attitude to innovation that is now widespread in the sector.

Figure 1 – The TIS key themes for innovative freight wagons. Credit: Technischer Innovationskreis Schienengüterverkehr (TIS)

Intelligent freight trains

If the sector wants to increase the competitiveness of rail freight transport significantly, the ‘innovative freight wagon’ can only be the first step. The real value of the many basic innovations only becomes apparent when we focus on the freight train as a whole.

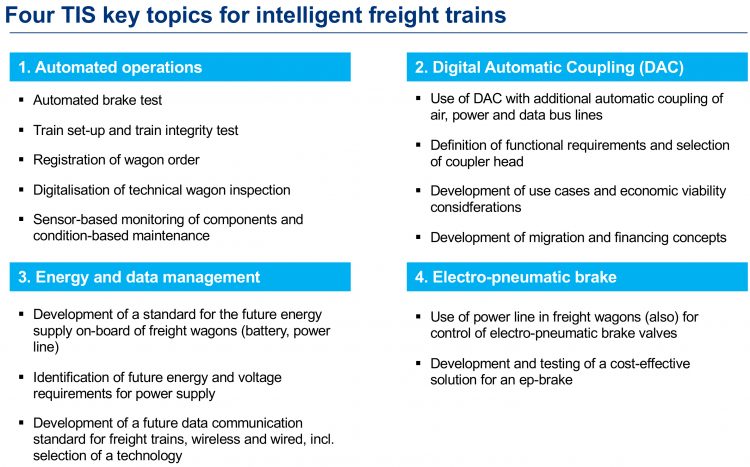

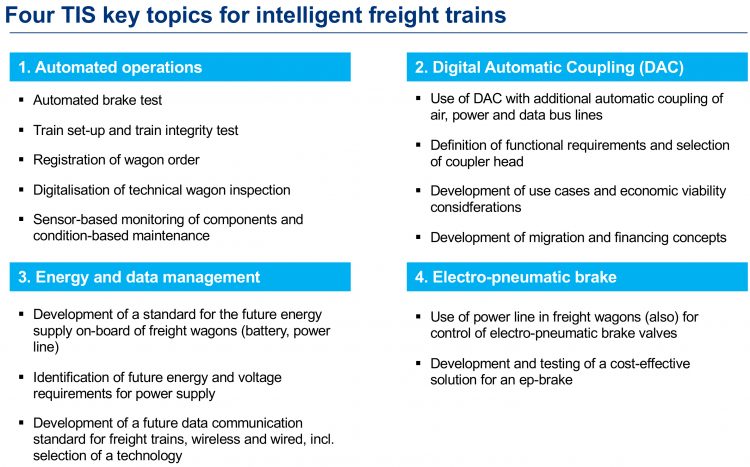

This is especially true in the digitalisation and automation of operational procedures in rail freight. The TIS is, therefore, taking the next logical step: Combining innovative freight wagons into intelligent freight trains. This offers enormous potential for increasing the efficiency and cost‑effectiveness of rail freight transportation.

The TIS is convinced that the automation of operations has a key role to play in boosting the competitiveness of the rail freight sector. Telematics applications offer a wide range of options for automating manual tasks with freight wagons/trains. The key will be to find solutions that completely replace all of the manual steps and visual inspections – not just simplify or shorten these individual operations.

The introduction of an automatic coupling will be the central component in the extensive automation of the rail freight sector. It will not only replace the manual coupling process, but will also provide an electrical power supply, as well as data communication in the freight train. Combining these functions in a digital automatic coupling with integrated power and data bus lines will open up considerable opportunities for rail operators. It is the key for delivering leaps in efficiency that will benefit the entire rail system. The position of the TIS is clear: The Europe-wide introduction of a digital automatic coupling must be made a top priority.

All previous attempts to introduce an automatic coupling (AC) for European rail freight transportation have failed. The companies participating in the TIS are all aware of this fact. In the meantime, however, the underlying conditions for the introduction of an AC have changed radically: Technological advances mean that the focus is no longer solely on improving the occupational health and safety of shunting staff or increasing the productivity of shunting operations. On the contrary, the introduction of an AC for freight trains could now generate a variety of additional benefits which considerably increase the competitiveness of rail freight transportation.

Simply automating the process of mechanical coupling – a standard practice in the U.S. and Russia for many years – is no longer enough. To achieve significant increases in productivity, the AC must also automatically couple the air, power and data bus lines. This will enable operators to automate many other processes which are currently performed manually. In the future, it may even be possible to develop an AC that can decouple by remote control.

The sector must develop a migration strategy for the aforementioned innovations and implement it in medium-term. This includes the agreement on a uniform, Europe-wide AC, as well as energy and data management standards for freight trains.

Figure 2 – The TIS key themes for intelligent freight trains. Credit: Technischer Innovationskreis Schienengüterverkehr (TIS)

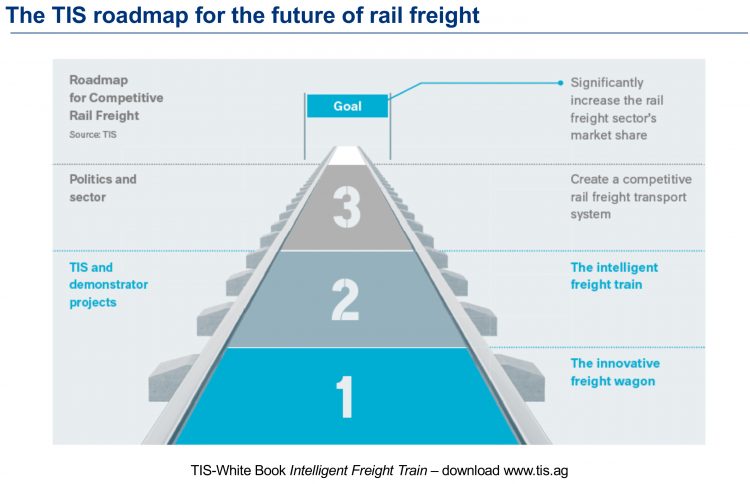

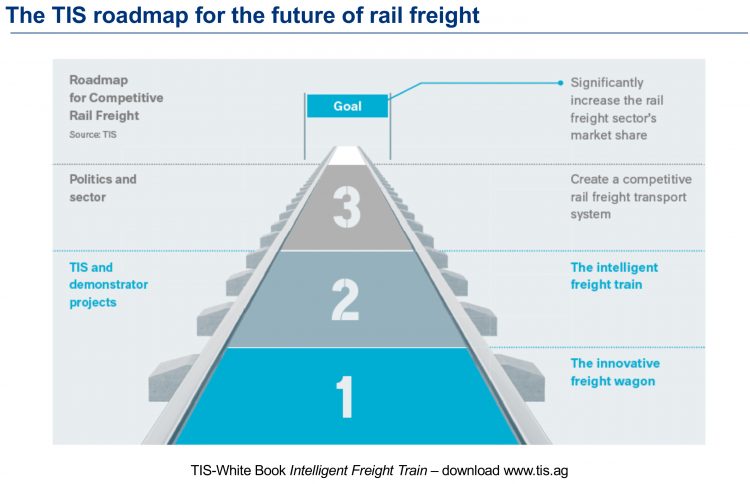

Making rail transport more competitive

Low CO2 emissions, an excellent energy balance, virtually no emissions of particulate matter: No other mode of transport is as safe and environmentally friendly as rail freight. It offers answers to the transport and climate policy challenges of the future. However, rail freight is under considerable pressure and the reasons for this lie both within and outside the industry.

The sector and the political sphere must, therefore, address many other improvements that affect the entire rail freight transportation system beyond the innovative freight wagon and the intelligent freight train. The competitiveness of rail freight can only be significantly increased if the necessary innovations and agendas are introduced in all three fields.

Without political and financial support, rail freight transport cannot, and will not, achieve its main goal – a significant increase in market share. Taking these factors into account, the rail freight sector requires an intelligent mix of research and funding programmes to promote and accelerate the rate of innovations.

Figure 3 – The TIS roadmap for the future of rail freight. Credit: Technischer Innovationskreis Schienengüterverkehr (TIS)

Outlook: The intelligent freight train

The roadmap to the intelligent freight train is complete. All agree that rapid progress is needed. Operations must be automated as a matter of urgency if the sector is to improve the efficiency of rail freight transportation – as well as find an answer to the significant shortage of skilled workers.

As a matter of principle – and, on this, all the companies involved in the TIS agree – automation of rail freight transportation cannot be implemented satisfactorily without the introduction of a digital automatic coupling. This is the central challenge facing the sector. Without agreement on a Europe-wide, standardised coupler head for an automatic coupling, there can be no successful migration.

Future energy and data management systems for European freight trains must also be built according to a uniform concept. Otherwise, automation will never emerge from its infancy. Consequently, the intelligent freight train of the future should only use wagons which are coupled using the same-still-to-be-defined technical standards, supply power for digital applications, transmit data in the same format and process it using the same technology.

Individual companies are highly unlikely to enjoy any success in dealing with these complex issues alone – unless they are largely engaged in closed-system rail transports which require little interoperability of freight wagons. In this respect, it is essential that companies beyond those involved in the TIS – such as shippers, wagon keepers and rail transport and infrastructure companies, as well as railway and supply industries – contribute to the innovation process in order to put the intelligent freight train on the railroad to success.

Issue

Related topics

Big Data, Cargo, Freight & Heavy-Haul, Digital Automatic Coupling (DAC), Digitalisation, Operational Performance, Rolling Stock Components (Interior/Exterior), Rolling Stock Orders/Developments, Sustainability/Decarbonisation, Technology & Software

Related organisations

BASF SE, DB Cargo, DB Systemtechnik GmbH, ELH Waggonbau Niesky GmbH, Ermewa SA, GATX Rail Germany GmbH, J.M. Voith SE&Co.KG, Knorr-Bremse Systeme für Schienenfahrzeuge GmbH, Rail Cargo Austria, SBB Cargo AG, Technical Innovation Circle for Rail Freight Transport (TIS), VTG Rail UK Ltd, Wabtec Europe, Waggonbau Graaff GmbH, Wascosa AG