The creation of railway digital twins through the convergence of IT and OT

Posted: 8 August 2018 | Diego Galar | No comments yet

As part of Global Railway Review’s Going Digital in Rail Week, Dr. Diego Galar, Professor of Condition Monitoring in the Division of Operation and Maintenance Engineering at Luleå University of Technology, explores how the adoption of IoT in railways and its use with OT platforms can enable the use of ‘digital twins’ to manage, monitor and maintain assets.

Historically, the information technology (IT) and operational technology (OT/operations) departments within a railway company have functioned somewhat independently. Operations kept the trains running smoothly and the infrastructure in good condition, while IT managed business applications from the front office. But railways are changing. To keep up, the IT/OT relationship must also change.

Railway leaders recognise that the operational data they use to support real-time decision-making could create additional value for the company. But this data must be merged with IT data in a meaningful way and made accessible across the organisation. With this fusion, IT will help OT align with business systems. At the same time, IT needs to achieve the vision of a connected railway by driving innovation and minimising downtime. But to get there, IT needs the knowledge and support of OT, as operations departments understand and control the assets.

Have your say on the future of the railways!

Diego Galar will be discussing the Internet of Things at our Digital Rail Revolution 2018, hosted in partnership with UIC in Paris on 21 November 2018. Click here to find out more.

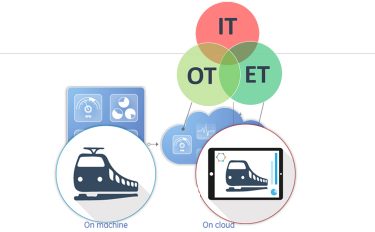

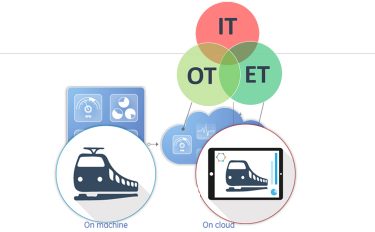

Through data fusion, railway digital twins become virtual and digital representations of physical entities or systems. However, the railway clone created with IT and OT convergence to forecast failures, demand, customer behaviour, or degradation of assets is not complete since it lacks engineering knowledge. This happens because the digital engineering models developed during the engineering phase of railway projects do not typically play a role in the operational phase.

Therefore, railway digital transformation demands that engineering technology (ET) be included in the IT/OT convergence process as the importance of integrating product design increases. For that purpose, railway digital twins must be complemented by other information to assess the overall condition of the whole fleet/system, including information from design and manufacturing, as this obviously contains the physical knowledge of assets.

Despite these challenges, hybrid models comprising engineering knowledge and data collected from the field will soon be part of digitisation all over the world.

In short, the engineering technology (ET) of a railway asset, together with IT and OT, will help O&M departments forecast problems, conduct better planning and improve performance. Fortunately, it is now possible for companies to merge their IT, OT and ET to enable asset performance modelling to deliver actionable intelligence for decision support.

Biography

Related topics

Big Data, Digital Twins, Digitalisation, Internet of Things (IoT), Technology & Software