Alstom demonstrate fully autonomous driving of a shunting locomotive

Posted: 2 December 2022 | Elliot Robinson (Editorial Assistant - Global Railway Review) | No comments yet

Alstom, in partnership with ProRail and Lineas, have demonstrated the highest grade of automation on a shunting locomotive.

Credit: Alstom

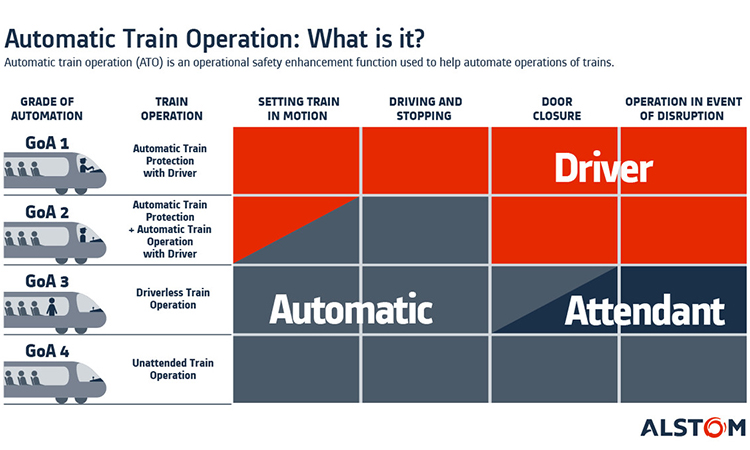

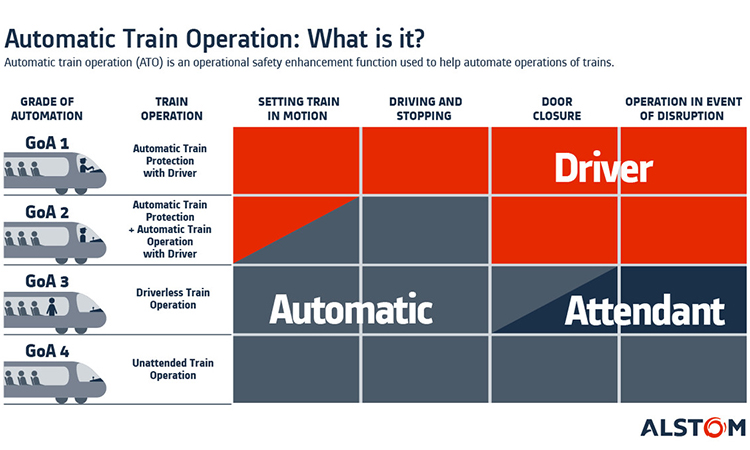

Alstom, in partnership with ProRail and Belgian rail freight operator Lineas, has demonstrated the deployment of Alstom’s Automatic Train Operation system (ATO) at Grade of Automation (GoA) 4 on a shunting locomotive for the first time near Breda, the Netherlands. This GoA4 means fully automated starting, driving, stopping, and the handling of unanticipated obstacles or events without the direct involvement of any on-train staff during shunting activities. This demonstration concludes a series of tests that are part of an ongoing partnership between Alstom, ProRail, and Lineas.

The ATO demonstration

The objective of the demonstration was to showcase how the intelligent obstacle detection and recognition system (ODS) works seamlessly with) Alstom’s ATO to allow the train to react autonomously to various obstacles. This paves the way for the broader usage of autonomous driving into shunting operations, with the goal of increasing the capacity of freight operations; an example of advanced digital technologies driving cost-effective and sustainable mobility in the face of growing demand for freight and passenger services.

“By integrating advanced obstacle detection into our autonomous driving systems, we have shown that it possible to make trains “see” ahead and cope safely with the unexpected,” Stéphane Féray-Beaumont, Vice-President of Innovation and Smart Mobility at Alstom, said. “The positive results prove that Alstom possesses the technology required to support operators with autonomous driving technologies that will ultimately improve the operational performance on freight lines. Through digitalisation, we will accelerate the transition towards more efficient, seamless, and sustainable transport systems.”

Credit: Alstom

For the demonstration, a diesel-hydraulic shunting locomotive owned by Lineas was equipped with the Alstom ATO technology interfacing with an intelligent obstacle detection and recognition systems (ODS) developed by NIART by Elta.

The locomotive, running autonomously, was presented with various obstacles – a person, a car, a rail wagon, and an incorrectly-positioned switch – and reacted entirely autonomously and without the intervention of any active staff aboard. The ODS proved to be effective up to 500 metres away from obstacles in real-world conditions, providing a significant safety buffer in shunting yards.

NIART’s ODS is a perception system based on high resolution digital radar fused with multi-spectral electro-optics powered by classical and machine learning algorithms to detect and classify obstacles on the train route in all weather and visibility conditions. The system is a complete, self-contained on-board solution able to provide the ATO system with the information it needs to make autonomous driving decisions.

ATO systems

Alstom is leading the development of ATO systems in the railway sector. The Group has carried out successful ATO tests in France, Germany, Belgium, the Netherlands, Switzerland, and the UK. The current tests at GoA4 being carried out in the Netherlands are designed to prepare the terrain for a wide range of applications in commercial operation on main lines across all grades of automation.

Alstom has demonstrated the advantages of ATO in metro transport systems around the world. Experience shows that automation leads to network capacity increase, cost reduction, energy savings and flexibility of operations. Automatic trains can run closer together, effectively increasing network capacity. Trains also operate more uniformly, leading to more effective use of energy. Automation in rail is a way for operators to maximise the productivity of their networks without making expensive changes to the infrastructure.

Related news you will enjoy:

Related topics

Automatic Train Operation/Autonomous Train Control (ATO/ATC), Depots & Shunting Yards, Operational Performance, Technology & Software