Leveraging state-of-the-art technology to improve the efficiency of India’s rail network

Posted: 16 April 2020 | Amit Kumar Jain, Manoj Krishna Akhouri | 1 comment

After the United States, China and Russia, India has the fourth largest rail network in the world, which is now struggling to cope with rising passenger and freight demands. As Manoj Krishna Akhouri and Amit Kumar Jain from India’s Ministry of Railways’ Centre for Railway Information Systems (CRIS) explain, state-of-the-art technology is being deployed to improve rolling stock operations on the country’s overstretched infrastructure.

The Banaswadi to Kochuveli Humsafar Express / Credit: Jayasankar Madhavadas

With a network of 67,000km, Indian Railways operates 13,000 passenger trains, carrying 23 million passengers, and 9,000 freight trains, transporting 3.05 million tonnes of freight, daily. With its very wide network touching almost every nook and corner of the country, Indian Railways play a crucial role in facilitating a balanced and inclusive socio‑economic development of the country. In the last 50 to 60 years, there has been a manifold increase in traffic without commensurate enhancement in the capacity of the system. As a result, Indian Railways is grappling with overstretched infrastructure, inadequate capacity, a dwindling market share in the freight sector and huge unmet passenger demand.

In this context, Indian Railways has decided to leverage new technology to improve the efficiency of the system in order to run more trains. One such initiative is a Real Time Train Information System (RTIS), which is used to track the location of trains in real-time through GPS devices installed in the locomotives.

Present system of train operations and management

Train movement data across Indian Railways is conventionally captured manually. The station master (SM) from every station relays a train’s arrival and departure by phone to the traffic controller (TC) or dispatcher. The TC marks the arrival or departure time of the train on a time distance chart – a ‘control chart’ – electronically. The planning and monitoring of trains is done through these control charts. Although the process of feeding information for control charts has been digitalised through Control Office Application (COA) for more than 10 years, the flow of information from the station level remained manual. Since Indian Railways operates both freight- and passenger-carrying trains on the same track, the TC plays a significant role in the efficient planning of train operations. They must decide when and where precedence is to be given to a fast-moving passenger train over a slow-moving freight train on a double-line section. The TC decides the crossing location of two opposite direction trains in a single-line section. A TC monitors and controls 20 to 30 trains running over approximately 25 stations within their area of control. Most of the time, the TC remains busy in manually collecting arrival/departure information and feeding it in COA, with very little time left for planning. The efficiency of train operation largely depends on the experience and competency of the TC. Moreover, the arrival/departure information fed by the TC in COA is also the source for real-time information given to customers regarding a train’s location and estimated time of arrival at the station. Any mistake on the part of the SM or TC results in wrong information being relayed to customers. In this context, the automatic acquisition of train movement data on Indian Railways on a real‑time basis is a key requirement for improving operational efficiency and the quality of passenger information. This requirement gained greater significance after implementation of ICT-based Control Office Application (COA) on all divisions of Indian Railways.

With a network of 67,000km, Indian Railways operates 13,000 passenger trains, carrying 23 million passengers, and 9,000 freight trains, transporting 3.05 million tonnes of freight, daily. With its very wide network touching almost every nook and corner of the country, Indian Railways play a crucial role in facilitating a balanced and inclusive socio‑economic development of the country. In the last 50 to 60 years, there has been a manifold increase in traffic without commensurate enhancement in the capacity of the system. As a result, Indian Railways is grappling with overstretched infrastructure, inadequate capacity, a dwindling market share in the freight sector and huge unmet passenger demand.

In this context, Indian Railways has decided to leverage new technology to improve the efficiency of the system in order to run more trains. One such initiative is a Real Time Train Information System (RTIS), which is used to track the location of trains in real-time through GPS devices installed in the locomotives.

Present system of train operations and management

Train movement data across Indian Railways is conventionally captured manually. The station master (SM) from every station relays a train’s arrival and departure by phone to the traffic controller (TC) or dispatcher. The TC marks the arrival or departure time of the train on a time distance chart – a ‘control chart’ – electronically. The planning and monitoring of trains is done through these control charts. Although the process of feeding information for control charts has been digitalised through Control Office Application (COA) for more than 10 years, the flow of information from the station level remained manual. Since Indian Railways operates both freight- and passenger-carrying trains on the same track, the TC plays a significant role in the efficient planning of train operations. They must decide when and where precedence is to be given to a fast-moving passenger train over a slow-moving freight train on a double-line section. The TC decides the crossing location of two opposite direction trains in a single-line section. A TC monitors and controls 20 to 30 trains running over approximately 25 stations within their area of control. Most of the time, the TC remains busy in manually collecting arrival/departure information and feeding it in COA, with very little time left for planning. The efficiency of train operation largely depends on the experience and competency of the TC. Moreover, the arrival/departure information fed by the TC in COA is also the source for real-time information given to customers regarding a train’s location and estimated time of arrival at the station. Any mistake on the part of the SM or TC results in wrong information being relayed to customers. In this context, the automatic acquisition of train movement data on Indian Railways on a real‑time basis is a key requirement for improving operational efficiency and the quality of passenger information. This requirement gained greater significance after implementation of ICT-based Control Office Application (COA) on all divisions of Indian Railways.

Real Time Train Information System (RTIS)

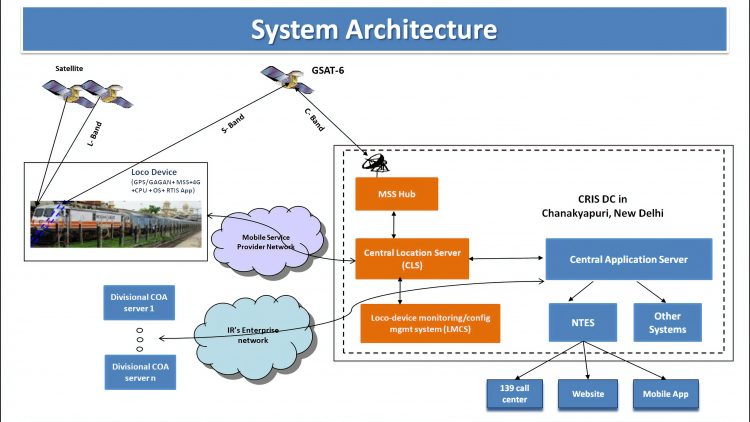

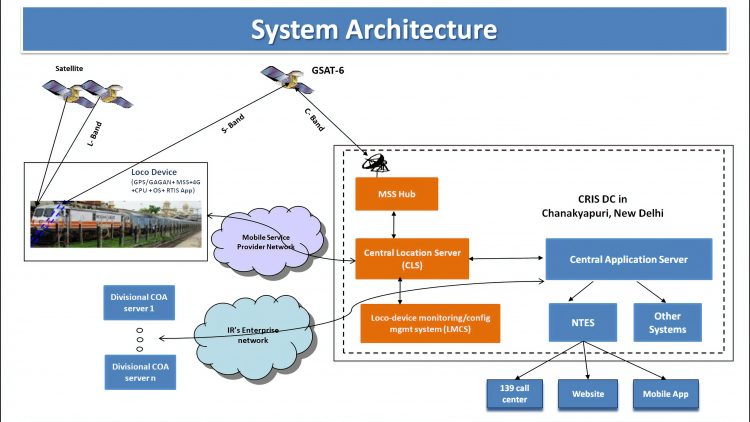

Indian Railways decided to adopt Internet of Things (IoT) for the automatic generation of train arrival and departure information from the train and automatic feeding of the same in COA. Under the Real Time Train Information System (RTIS) project, approximately 2,700 electric locomotives running on Indian Railways’ network have been equipped with satellite devices. A RTIS locomotive device comprises of an indoor unit installed in the locomotive cabin and an outdoor unit installed on the locomotive roof-top. The RTIS application software in a locomotive’s device determines train movement events i.e. arrival, departure, run-through (ADR) at stations and en-route location updates at 30 second intervals, based on pre-defined logic applied on spatial coordinates and speed received continuously from the satellite receiver. A RTIS locomotive device has an Intel Atom processor, adequate memory and a Solid State Drive (SSD). Satellite communication service is used for communicating locomotive movement updates to the data centre, where it is processed and forwarded to the COA server of Indian Railways. The ADR events, along with position/location updates, are communicated to a Central Location Server (CLS) using the satellite communication service, as well as 4G/3G mobile data service. The CLS processes the data received and relays it to a train control application for the automatic plotting of control charts. As train control application is already integrated with the National Train Enquiry System (NTES), accurate real-time information of train running is relayed to passengers. The system architecture of RTIS is shown in Figure 1.

Figure 1

Remote monitoring and management of locomotive system (REMMLOT)

The new Indian Railways diesel locomotives are equipped with GPS devices for monitoring the health of the locomotives. This system comprises of an on-board sensor, GPS receiver and processor panel etc. that can capture, process and communicate data through GPRS service to a common web server for further processing of data. REMMLOT in diesel locomotives is also used for capturing train arrival and departure information and communicating the same to COA.

Benefits of IoT in locomotives (RTIS and REMMLOT)

There are several benefits of deploying IoT in locomotives, including:

- The movement of the trains is automatically plotted on control charts, including mid-section plotting. As such, the TC is free to plan train operations efficiently

- Since arrival/departure information comes through the RTIS device, customers receive accurate information about a train’s location on a real-time basis

- Even if the locomotive is not attached to a train, the exact location of the locomotive can be tracked through RTIS

- The system can be used to generate customised Management Information System (MIS) reports to analyse the punctuality of trains, on route loss of time and observation of engineering speed restrictions

- Accurate train running information leads to optimum crew booking and reduction in pre‑departure detention (PDD)

- Emergency messaging service in RTIS provides a single touch messaging facility to locomotive pilot, which can be used in the event of unusual occurrences, such as an OHE problem, engine problem, track-related problem, infringement, derailment etc.

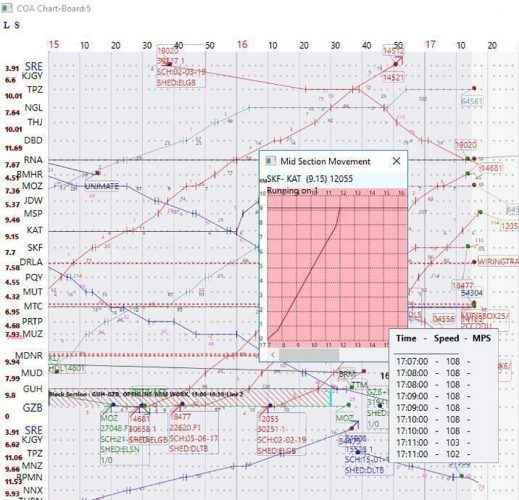

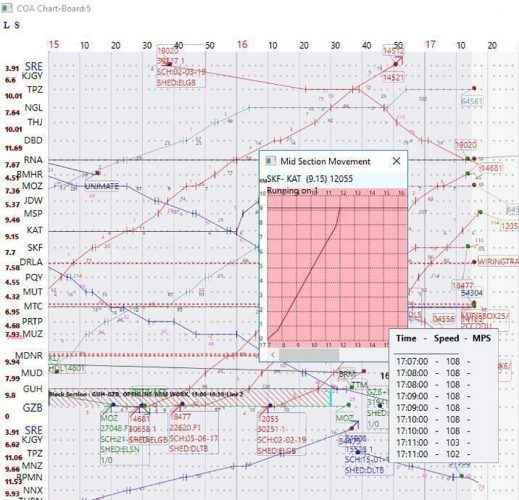

- RTIS generates the speed profile of the train, as shown in Figure 2. The TC can monitor the speed profile to check whether the train is running as per scheduled speed and following the engineering speed restrictions – the efficiency of the train driver can be assessed through the RTIS system

- In case of Signal Passing At Danger (SPAD), RTIS data can be used to find out the exact location of the locomotive at the time of the incident

- Determining unscheduled stoppages of a train on its journey.

Figure 2

Present stats of RTIS over Indian Railways

RTIS devices have now been installed in 2,700 electric locomotives. Train movement updates from these locomotives are being forwarded to COA through Enterprise Service Bus (ESB). Train control chart plotting is automated and simultaneous information is provided to the public through the National Train Enquiry System (NTES). Mid-section chart plotting is also performed in all 69 divisions of Indian Railways. RTIS Phase 2 roll out, covering 6,000 more electric locomotives, is planned to be completed by December 2021.

Potential use of RTIS in the future

At present, RTIS is mostly used for the automatic arrival and departure of trains in COA and conveying the real-time status of trains to users through the NTES. CRIS is working on further utilising RTIS data for the following purposes:

- Entry and exit of locomotives in and out of depots where locomotives are maintained and to estimate output of depots with respect to targets

- The expected travel time (ETA) of a train can be worked out on the basis of the actual running of the train. Artificial intelligence (AI) tools are planned to be deployed for realistic estimation of ETA

- The driver can be alerted in advance about the location of a speed restriction imposed due to track defects. Should the driver operate the train at a speed higher than is permissible, the system can generate an alarm and may automatically apply brakes, if RTIS is integrated with the braking system of the locomotive

- The customers are required to load or unload goods train within a specified time, beyond which penalty (called demurrage) is imposed for detention of the goods train. Presently, the time of arrival and departure of freight trains on freight handling lines (called goods siding) is entered manually, which sometimes results in disputes between railways and the customer

- RTIS is planned to be used for automatic placement of goods trains in sidings. The efficiency of train operations largely depends upon the workmanship of the train driver. The time taken by the driver in achieving maximum permissible speed, maintaining it, observing speed restrictions, braking etc. impacts the run time of the train and consequent punctuality. The train’s energy consumption can also be controlled by optimal driving, such as running the train in coasting mode whenever feasible, optimal regenerative braking and observing speed restrictions. RTIS can be used to assess the performance of the train driver in maintaining punctuality and also with respect to energy consumption

- Network Optimisation: The train running data can be used for the advance plotting of the trains and to suggest an optimal non‑congested route, considering all trains running over the section

- Re-scheduling of trains: In case of a late running train, the train (link train) which is scheduled to be run by the same trainset needs to be rescheduled and passengers need to be informed in advance. RTIS can be used for the automatic rescheduling of the link train on the basis of the real time status of the main train

- The on-board passenger information system can be integrated with RTIS for announcements on trains about the next stop.

The way forward

Indian Railways is deploying state-of-the-art technology to improve train operations. RTIS is one such step in this direction. With approximately 50 per cent of Indian Railways’ locomotives equipped with RTIS/REMMLOT devices, 14 million events are being generated on a daily basis. Indian Railways is working to equip all locomotives with RTIS devices and to use real‑time data to improve train operations, by using AI to improve the accuracy of ETA of trains, entry/exit of locomotives in depots, placement/removal of goods trains in goods sidings and the rescheduling of trains. With these possible use cases, RTIS has the potential to become the Internet of Trains (IoT).

Issue

Related topics

Artificial Intelligence (AI), Cargo, Freight & Heavy-Haul, Digitalisation, Infrastructure Developments, Operational Performance, Passenger Experience/Satisfaction, Passenger Information Systems (PIS), Real-Time Passenger Information (RTPI), Technology & Software

Trains in India are always impressive when people travel on the roof of wagons and steps … I think that India has long had a question about the need to use technology!